-

PCD3.W2xx

-

Analogue input modules

-

Documentation

System Catalogue : PCD3

| Extract | 26-215_A0120 | System Catalogue : PCD3 |

PCD3.W200 - Analogue inputs, 0…10 V, 10 bit

| Datasheet | 31-627 | PCD3.W200 - Analogue inputs, 0…10 V, 10 bit |

Analogue input module, 8 inputs (channels), resolution 10 bit, signal range 0 … 10 V, (the channels themselves not separated), connection with pluggable spring terminals, plug-in type A (4 405 4954 0) included

| ENG05 |

|

1.06 MB | Download | ||

| FRA05 |

|

1.06 MB | Download | ||

| GER05 |

|

1.05 MB | Download | ||

| ITA05 |

|

1.05 MB | Download | ||

| SPA05 |

|

1.05 MB | Download |

PCD3.W210 - Analogue inputs, 0…20 mA, 10 bit

| Datasheet | 31-628 | PCD3.W210 - Analogue inputs, 0…20 mA, 10 bit |

Analogue input module, 8 inputs (channels), resolution 10 bit, signal range 0 … 20 mA (4 … 20 mA via software), the channels themselves not separated, connection with pluggable spring terminals, plug-in type A (4 405 4954 0) included

| ENG03 |

|

1.00 MB | Download | ||

| FRA03 |

|

1.01 MB | Download | ||

| GER03 |

|

1.01 MB | Download | ||

| ITA03 |

|

1.01 MB | Download | ||

| SPA03 |

|

1.05 MB | Download |

PCD3.W220 - Analogue inputs, Pt/Ni1000, 10 bit

| Datasheet | 31-629 | PCD3.W220 - Analogue inputs, Pt/Ni1000, 10 bit |

Analogue input module, 8 inputs (channels), resolution 10 bit, signal range Pt / Ni1000, (the channels themselves not separated), connection with pluggable spring terminals, plug-in type A (4 405 4954 0) included

| ENG04 |

|

1.06 MB | Download | ||

| FRA04 |

|

1.06 MB | Download | ||

| GER04 |

|

1.05 MB | Download | ||

| ITA04 |

|

1.06 MB | Download | ||

| SPA04 |

|

1.06 MB | Download |

PCD3 Hardware

| Manual | 26-789 | PCD3 Hardware |

IO-Modules

| Manual | 27-600 | IO-Modules |

Systemcable and adapter

| Manual | 26-792 | Systemcable and adapter |

Z02, Z12, Z15, Z25 & Z29

| Internal Info | Z02, Z12, Z15, Z25 & Z29 |

Internal documentation about the special versions Z02, Z12, Z15, Z25 and Z29 mentioned in some technical informations

| DE |

|

|

0.21 MB | Download |

PCD3 / Wxxx

- Why are the inputs and outputs of a PCD3 systems not switched on and off correctly, or switched on and off randomly, or the I/O status not detected correctly in the PLC? (FAQ #102063)

- On a PCD2.M4560 or PCD3.M5560, why the measured PT100 temperature values are not correct if the PT100 sensors are connected to PCD2.W220Z18 or PCD3.W220Z18 modules? (FAQ #102052)

- Why do measured input values for PCD2.W3x5 / PCD3.W3x5 cards "freeze" (FAQ #102043)

- Why do the 0 to 10 V analog outputs of the PCD3.W800 cards 'freeze' to a random value during operation and cannot be controlled by the user program? (FAQ #102028)

- Why do the output of the PCD2/3.W6x5 not deliver stable signals? (FAQ #102014)

- How to read the diagnostic information of a PCD3.W745 on a PCD3.T760? (FAQ #101697)

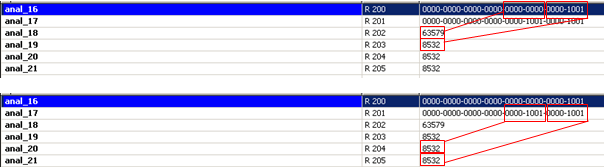

- Why are analogue entries of the PCD3.W745 displayed incorrectly when using the memory mapping? (FAQ #101672)

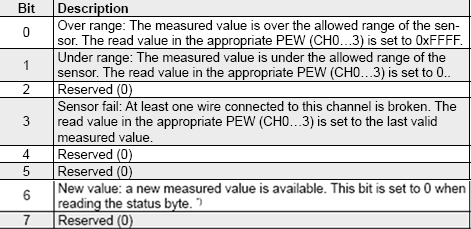

- What is the signification of the I/O words of a PCD2/3.W525 module? (FAQ #101552)

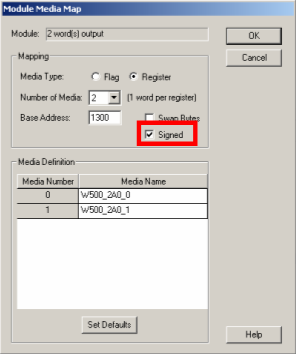

- Why do I get wrong values when reading a PCD2/3.W340 with media mapping? (FAQ #101416)

- What exactly is a PCD2/3.W721 and can I order it? (FAQ #101247)

- Why do the outputs of PCD2/3.W525 not work? (FAQ #101204)

- Replacement possibilities for PCD2.W5x0 and PCD3.W5x0 modules (FAQ #101151)

- PCD3.W800: how to detect if an output channel is in forced state (FAQ #101063)

- Which module to use for Pt100 / Ni100 measurements? (FAQ #101032)

- Can PCD2/3.W3x5 module measure "overrange values"? (FAQ #100955)

- On the Profibus-DP or Profi-S-I/O master it isn't possible to read or write registers with address > 4095 from the slave (FAQ #100927)

- Connecting "special" temperature sensors to analogue modules. (FAQ #100926)

- Why is the range of analogue (current-) input modules specified as 0(4)..20 mA? (FAQ #100675)

- Analogue modules read wrong values while beeing online with PG5 (FAQ #100631)

- How to connect two-wire current converters? (FAQ #100623)

- Shall the terminal 16 of the PCD2/3.W745 be connected to ground? (FAQ #100604)

- How to configure the PCD3.W800 and A810 on an RIO Module PCD3.T760? (FAQ #100570)

- Are the modules PCD3.W800, PCD3.A810 and PCD3.A860 supported by the PCD3.T760? (FAQ #100504)

- What is the reason for the error "underflow" of the PCDx.W745? (FAQ #100499)

- Frozen PCD2/3.W3x5 and PCD2/3.W6x5 modules (FAQ #100475)

- Negative values from PCD3.T760 are not interpreted correctly on the PCD (FAQ #100466)

- Sampling time of PCD2/3.W6x5 modules (FAQ #100395)

- How to configure a PCD3.W745 on a PCD3.T760? (FAQ #100214)

- Why do PCD3.Wxxx input modules placed on an extension modules PCD3.Cxxx not work properly? (FAQ #100054)