By default, the outputs of a the modules mounted on a PCD3.T360 RIO will be reset on bus failure (or if the master is in STOP or HALT). This is the general defualt behaviour on Profubus DP networks that was overtaken for the Profi S-I/O networks.

Why are the outputs reset?

This behaviour generally does improve the security of the system. In case there is e.g. a motor controlled by the module mounted on the PCD3.T760, this motor must be stopped as soon as it isn't guaranteed any more that the master does have the control over the actions taken by the motor.

Is it possible to define the states of the outputs otherwise?

Yes, the "preferred state" of the outputs can be defined for each output. This means the it is possible to define the state of each output on bus failure.

It is also possible to configure a module in a way that the last written output state remains also on bus failure.

How is the preferred state of the outputs configured?

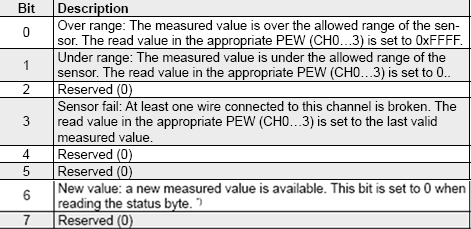

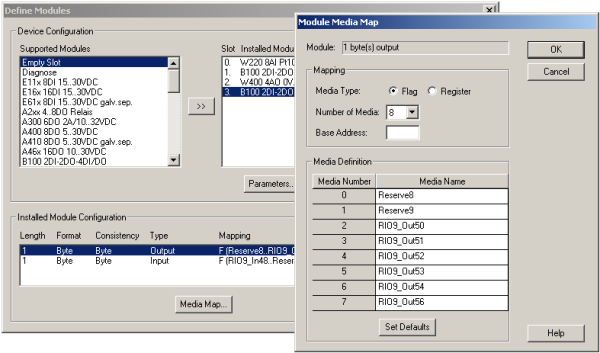

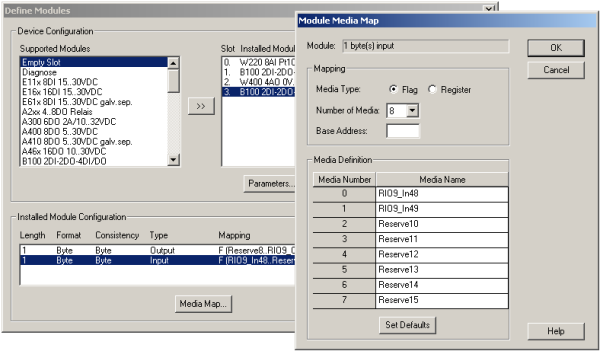

The configuration of the preferred state is done via the extended diagnostic module of the RIO. In this module, 4 output bytes (written to to T760) and 4 input bytes (status information from the T760) are present.

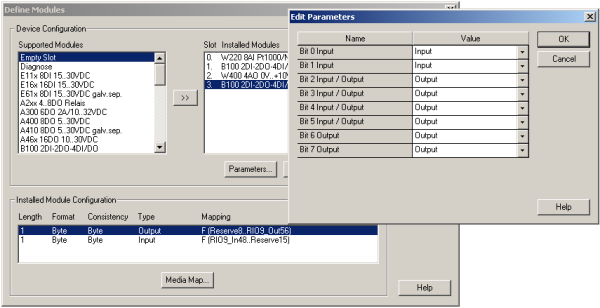

Configuring a digital module on the PCD3.T760 for keeping the last value

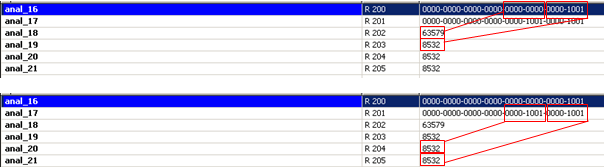

In order to define the preferred output state in case of bus error in a the way that the last value is retained, the command value 3 is to be written in byte 3 of the diagnostic output bytes. Additionally, the address of the module is to be given in the bits 0..3 of the output byte 2. The information that the last value shall remain on bus error is given in bit 7 of the output byte 2.

Output bytes

| Byte 0 |

Byte 1 |

Byte 2 |

Byte 3 |

| not relevant *) |

not relevant *) |

Module position |

Command |

| 0 |

0 |

binary: 10000011 |

3 |

This example shows the command for retaining all output values of the module 3 (fourth slot of the T760). The indication for the module 3 is given in bit 0..3 of byte 2 (binary 011=3). The indication for retaining the last value is given in bit 7 of byte 2. If the state of all the outputs of the concerned module shall be retained, byte 0 and byte 1 are irrelevant (they are used for e.g. setting a preferred state 0 or 1).

The T760 will return the same values in the diagnostic input (also 4 bytes) if the command is accepted.

Please refer to the chapter "Diagnostic information on RIOs" of the PCD3 manual 26/789 for the complete description of the extended diagnostic of the PCD3.T760.