239

saia-pcd.com

2

Communication &

Interaction

SBC S-Web Technology

1

SBC Software

3

SBC S-Web Technology

Adjusting S-Web projects following acceptance

The S-Web applications of a Saia PCD® automation station can

be adjusted and expanded completely independently of the local

regulation/logic project. The core ICA functions are realised using the

Saia PG5 software tool and loaded into the Saia PCD®. The Saia PG5®

Web Editor can also be used to load new S-Web applications into the

Saia PCD®. It is also possible for several S-Web projects to work on one

and the same automation device in parallel. This makes it possible

to create sub-projects for specific user groups (e.g. for service or

operators). It is thus possible to influence the diversity of the browser

devices being used.

S

Several HMI applications adjusted/optimised to the

respective user groups are possible on one controller.

Using Saia PG5® HeaVAC Lib- and Saia PG5® DDC Suite templates

The Saia PG5® HeaVAC- and Saia PG5® DDC Suite library provide the user with a collection of pre-assembled function and system

objects with graphical templates. They are designed for primary HeaVAC technologies and general building automation systems.

The templates can be transferred unaltered and also adjusted to meet the conditions of the application if necessary. A detailed

description of the libraries can be found in Chapter B1 Software.

Templates

S

Web Editor contains comprehensive template and graphics libraries for the programmer for efficient engineering.

It is also possible to create your own templates.

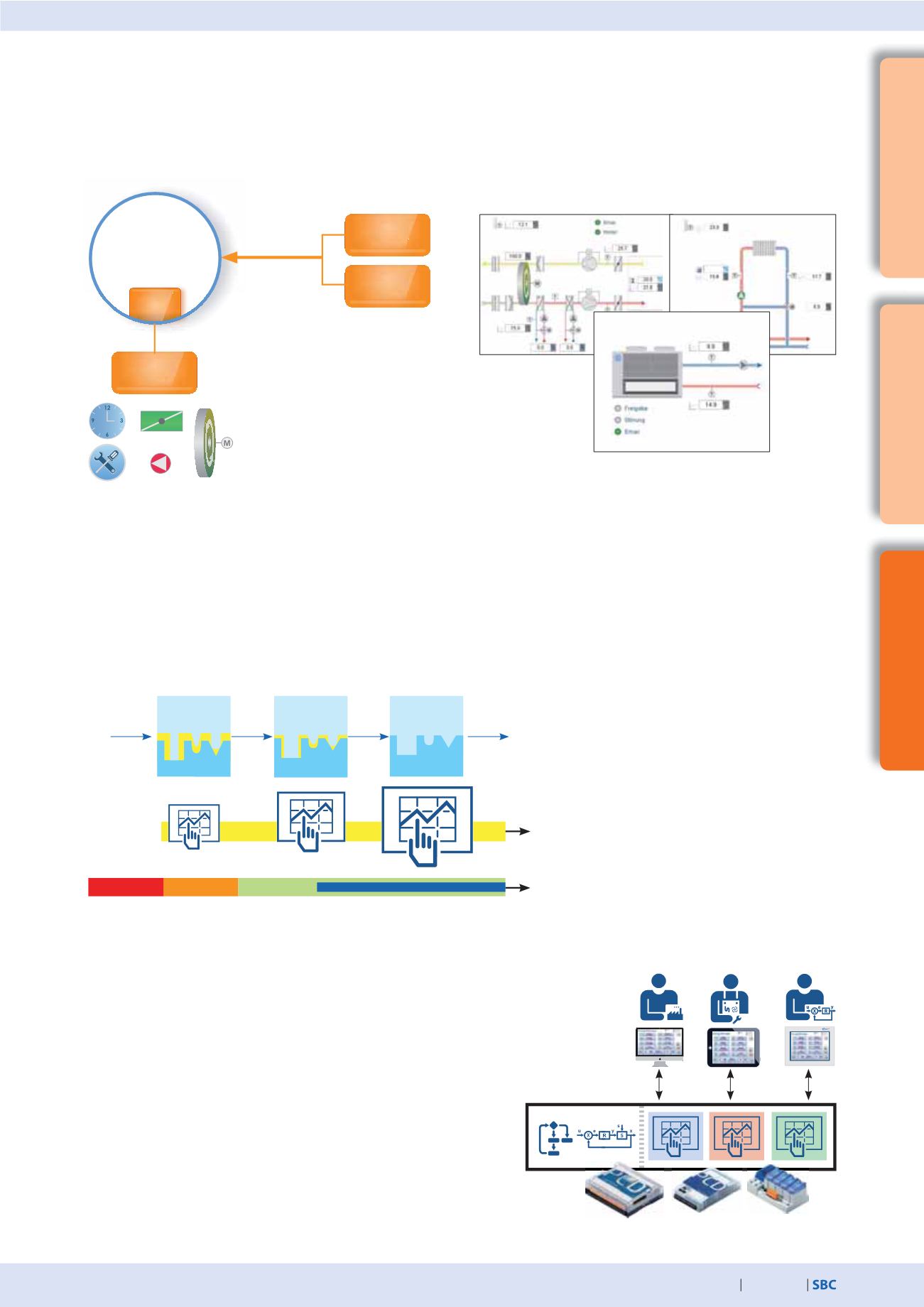

Little time required to create a successful result

Saia PG5® Web Editor makes it possible to achieve a “basic fit” quickly and efficiently. This means that the basic necessary

functions for acceptance are realised.

The SBC S-Web application can be adjusted at any

time during the initial optimisation phase of the

system and later during continuous operation to

meet the actual, individual requirements. The way

to good fit and perfect is always open, nothing is

installed and nothing is closed off.

Maintenance

supervisor

in the office

Service engineer

on the road

ICA specialist

Graphic icon

library

My Templates

HVAC-Lib

DDC_Suite

Libs

SBC

S-Web Editor

S

The maximum degree of engineering freedom is given over the entire life-cycle for

optimisation and adjustment; for operator, installer and service provider.

15–20

years

Request

operation

Automation

solution

Basic Fit

Automation

solution

Good Fit

Request

operation

Automation

solution

Perfect Fit

Request

operation

On

delivery

Plan

Realise

Optimise Operate