233

saia-pcd.com

N

S

E

NW

NE

+ + =

2

Communication &

Interaction

SBC S-Web Technology

1

SBC Software

3

SBC S-Web Technology

3.5

Tender information

What is the difference with S-Web?

Management level

Field level

Automation level

The on-site technology is mainly determined by the planning and tender specification processes. In single incremental

developments, it is enough to continue maintaining existing planning and design specification standards. However,

if the technological development results in large structural changes, the planning process also requires large changes which

can then affect the resulting tender specification. This chapter is a guide for planners who want to further develop their tender

specification standard in this sense.

Technical basis of the “old”

automation pyramid

`

Replacement of the analog

control technology

`

Master Slave

`

MHz/MByte PC technology

`

Proprietary/closed technology

Functional structure of “old” automation

pyramids

Automated system’s core function distributed

across various levels and different devices

Proprietary number of different buses, gateways

and expensive integration. “Total integration” is

propagated as an “emergency” solution by large

manufacturers.

Total integrated system pyramid

Everything from a single source.

Single operator. Opposite of lean.

Functional structure of “lean” automation

pyramids

All core functions of the automated system

possible in one device.

Interaction of all devices via Web+IT standards.

Integration from field to control layer

provided via LAN/WAN.

Technical basis of “lean”

automation pyramids:

`

Replacement of dedicated

control/management PCs

`

Client Server/local remote

`

GHz/Gigtye technology

in automation device

`

Web+IT technology/open for

all

SBC S-Web is an innovative system comprising a combination of technical innovations and non-proprietary, globally recognised

technologies. It has therefore been steadily developing for more than 10 years.

SBC S-Web is causing a paradigm change in automation technology in terms of operation, monitoring and management.

It makes the boundaries of the classic automation pyramids transparent and integrated, both internally and externally.

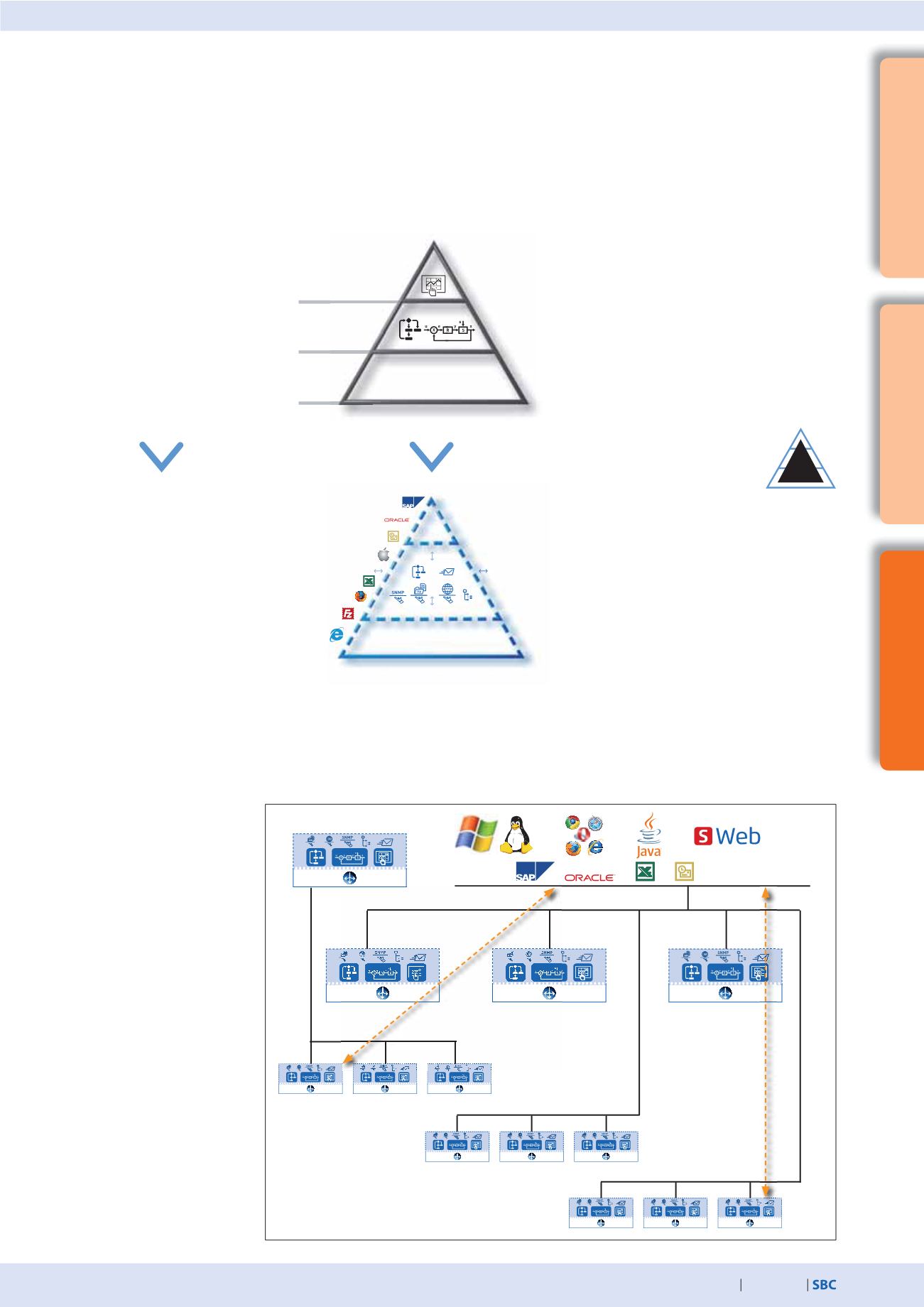

Structure of lean

automation systems

All the measurement/control

devices of this structure have

the same functional structure

and capabilities

= PLC +Web + IT

Each automation device

can have relationships

in the client and the server

to every other automation

device and residual web/IT

technology in the property.

This makes it possible

to maximise use, reduce

operational expenses

and create a highly flexible

life-cycle.

But what does this mean for

the tender specifications?

X

Lean automation system: all core

functions of the automation

(PLC+Web+IT) integrated in that

automation device enable

the integration and interaction

of all devices from the field level

to the control level.