244

saia-pcd.com

PCS1

PCD3

Compact

PCD1

PCD2

PCD3

•

•

•

•

•

(•)

•

•

•

•

•

•

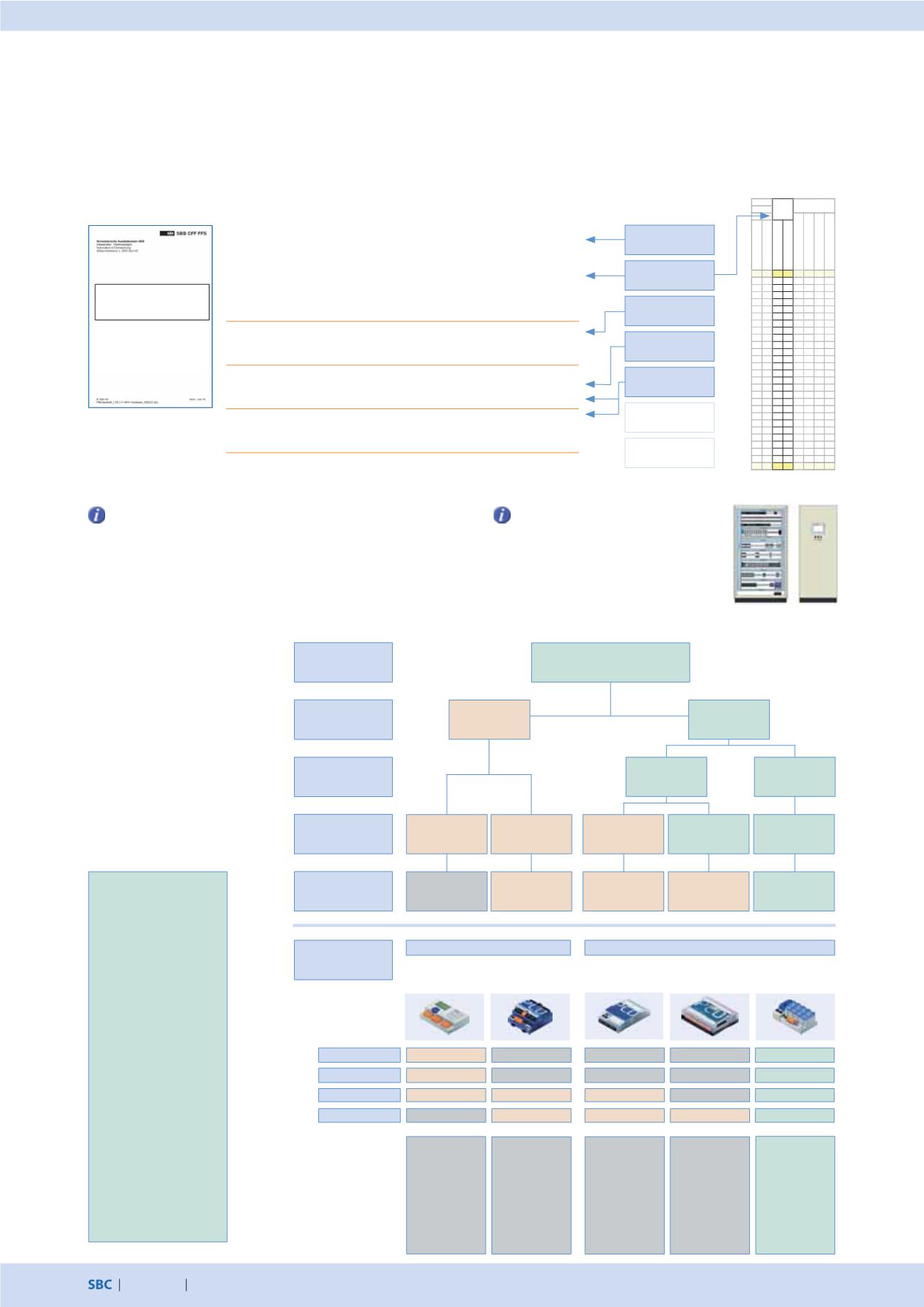

Sample Project

Planning Guide

Description:

Two stage partial air conditioning system with

plate heat exchanger, air heater and air cooler.

Ventilation with manual/emergency operation.

A control cabinet is to be provided for the installa-

tion of electrical and automation technology.

Controller:

Flexible, modular and expandable

controller

Interfaces:

Basic interfaces – Ethernet / USB

energy

measurement M-Bus; expandability option

Expansion reserve:

At least 20 % expansion reserve

Data:

Recording/storage of operational data

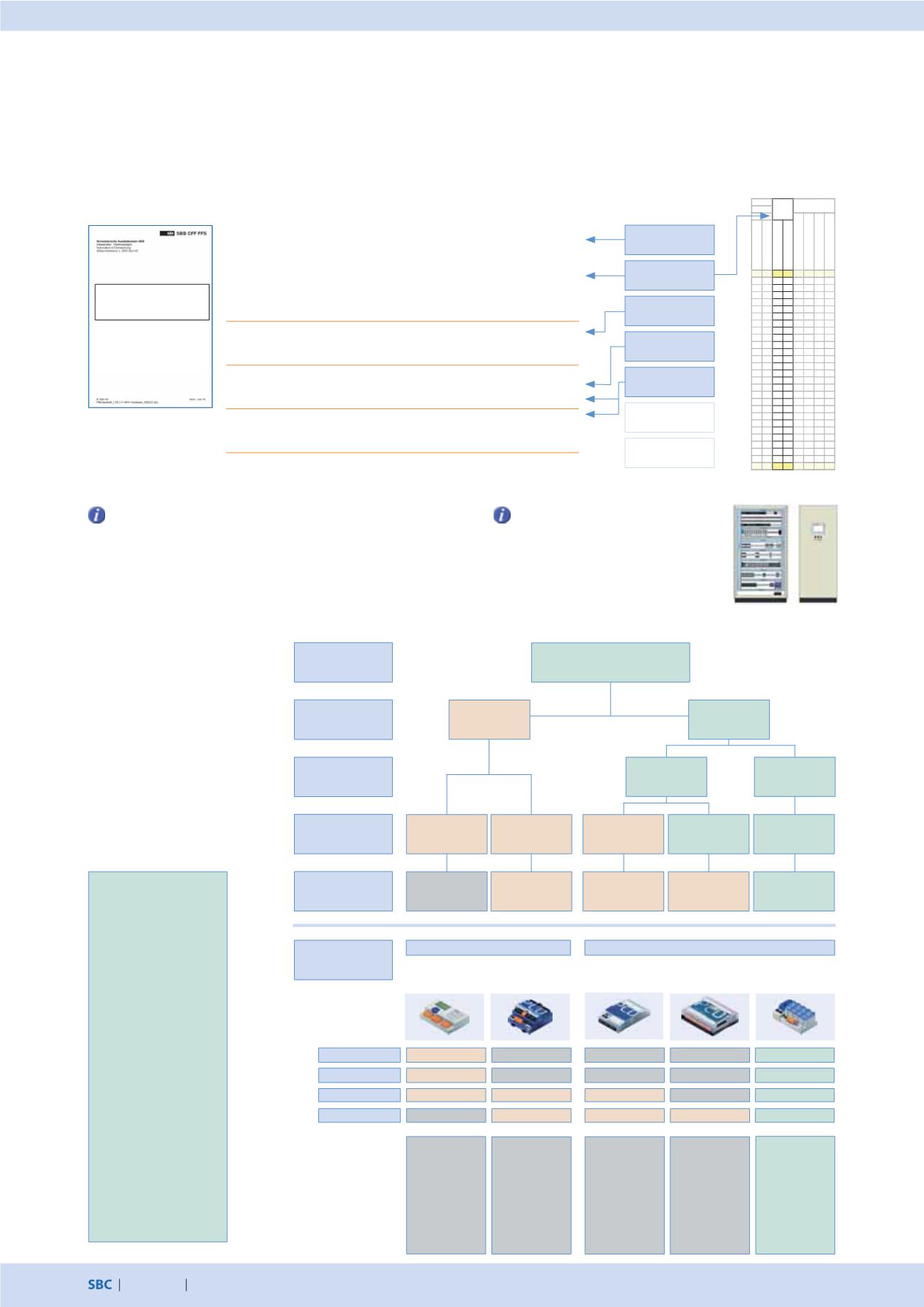

2.

Definition of device family

System selection

Device families PCD1 /

PCD2 and PCD3 meet

the specification re-

quirements regarding

basic communications

interfaces.

Device families PCD2

and PCD3 meet

the requirements

for modularity and

expandability.

Based on its direct

manual/emergency

operation capability,

the PCD3 family is

chosen.

For further selection

criteria, see steps 3

and 4.

Saia PCD® devices as user programmable instrumentation, control and automation (ICA) equipment with a design that is either flat,

compact or cassette-type. Modular and expandable device series with enough reserves to allow expansion of communications for the

device family.

Requirement from specification

Specification

Data memory

In-/outputs

Selection criteria

Communication

Mounting location

Manual operation

Expandability

Modularity

Mounting

location

Modularity

Manual opera-

tion

Expandability

Form

Switch cabinet

Compact

Modular

Flat

up to 1024 DP

up to 50 DP

up to 102 DP

up to 44 DP

NO

NO

YES

NO

Cassettes

up to 1024 DP

YES

D

EVICE

FAMILY

System families

Ethernet/USB

Modularity

Expandability

Manual operation

Meets require-

ment only

in manual/

emergency

operation

Meets require-

ment of basic

interfaces with

reduced ex-

pandability.

Without man-

ual/emergency

operation

Similar to the

PCD3 family

with reduced

expandability.

Without man-

ual/emergency

operation

Meets require-

ment of basic

interfaces and

expandability.

Without man-

ual/emergency

operation

Meets

requirements

of basic com-

munications,

expandability

and manual/

emergency op-

eration

C

OMPACT

M

ODULAR

Maximum PLC flexibility

Sustainable automation solutions require maximum flexibility in ex-

pansion and function. The greater the need for flexibility and expand-

ability, the more weight should be placed on open, modular systems.

The basic "USB / Ethernet" communication interfaces for program-

ming and data exchange are the basis for sustained system usability.

Mounting in control cabinet

Modular systems are generally used when

mounting is required inside closed electri-

cal control cabinets. The «Flat» or «Cassette»

system forms do not differ in function, but may

affect space availability in the cabinet.

Project:

Control and fault reporting

system Switzerland LSS-CH

PLC automation equipment

Specifications

tions

Emerg.

con-

trol

Control

functions

puts

$(

Graphic/System image

Dynamic insertion

(YHQWLQVWUXFWLRQ

0HVVDJHWRH[WHUQDOVLWH

Reading active

Reading passive

Switch/Set

View

8 9 1 2 n1 n2 n3 n4

1 5 1 1

1

1

2

1

3 ? ?

1 1

1

2

1

1 1 1

2 3

9 3 3

1 1

1

2

1

2

1

2

1 2

6 1 1

1 2

6 1 1

1

2

1

2

1 1

2 3

9 3 3

1

3 ? ?

1

2

0 6 10 11 0 62 13 10

eading ac

eading pa e

n

Q