245

saia-pcd.com

PCS1

PCD3 comp.

PCD1

PCD2

PCD3

Sample Project

3

Type Index

2

Product launch

1

Planning Guide

Planning Guide

3.

Definition of communication

Saia PCD® systems offer appropriate communication protocols to connect related building systems throughout the automation pyramid. The

greater the number of expandable communication interfaces, the more flexible and sustainable the automation system.

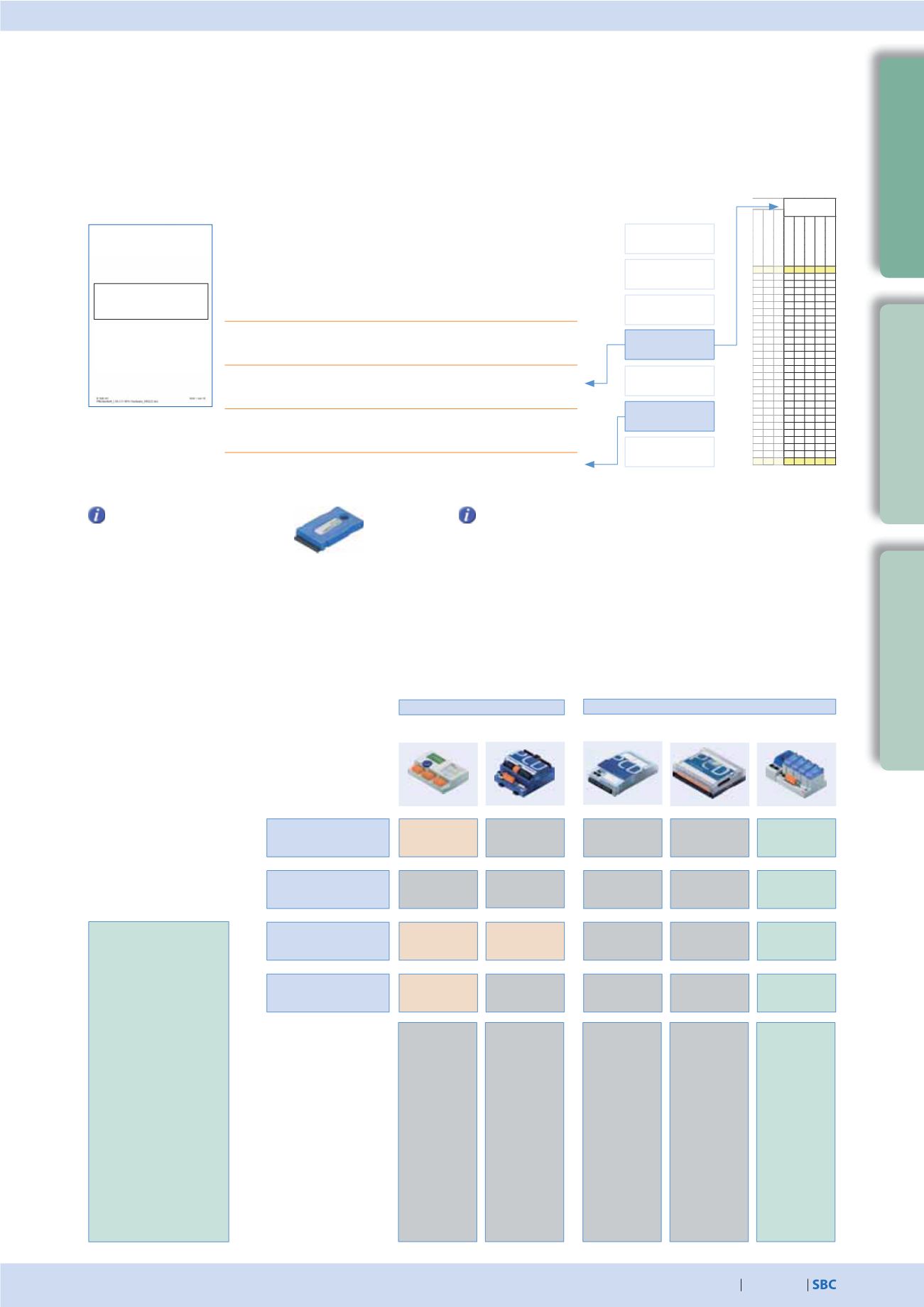

System selection

Communication re-

quirements as to the

number and type of

interfaces are largely

met by PCD2 and

PCD3 systems.

The PCD1, PCD2

and PCD3 have data

memory and file

systems.

In combination with

the «Device family»

selection, a choice

is made for the

Saia PCD3 system

family.

Description:

Two stage partial air conditioning system with

plate heat exchanger, air heater and air cooler.

Ventilation with manual/emergency operation. A

control cabinet is to be provided for the installation

of electrical and automation technology.

Controller:

TFlexible, modular and expandable controller

Interfaces:

TBasic interfaces – Ethernet / USB energy

measurement M-Bus; expandability option

Expansion reserve:

TAt least 20 % expansion reserve

Data:

TRecording/storage of operational data

Requirement from specification

M

ODULAR

C

OMPACT

Operating data is recorded/stored

on optional flashmemory (e.g.

PCD7.R551M04) according to CPUmodel.

Data is managed via the integral file

system.

An M-Bus connection to the meters of

various manufacturers can be integrated

into Saia PCD® systems via an external

gateway or with an integral interface

module. Integrated implementation

saves costs and wiring.

Specification

External

External

Internal

Internal

Internal

M-Bus

4

4

8

15

13

Interfaces

•

•

•

•

Data memory/file

system

1

2

2

2

Ethernet port (switch)

Meets

requirements

for field and

meter bus.

However,

does not

have any data

memory or

Ethernet port.

Meets

requirements

for commu-

nication and

data memory.

However, the

lack of an

integral inter-

face for M-Bus

reduces opti-

mum use.

Meets

requirements

for commu-

nication and

data memory.

However,

with reduced

expansion

potential at

interfaces.

Meets

requirements

for commu-

nication and

data memory

with high

capacity.

Fully expand-

able com-

munications

in field and

automation.

Meets

requirements

for commu-

nication and

data memory

with high

capacity.

Fully expand-

able com-

munications

in field and

automation.

Mounting location

Manual operation

Expandability

Modularity

Communication

Data memory

In-/outputs

Selection criteria

Control

functions Communications

I/O functions

*UD¿N$QODJHQELOG

Dynamic insertion

(YHQWLQVWUXFWLRQ

0HVVDJHWRH[WHUQDOVLWH

Switching

Specify/Setpoint

Reporting

Counting

Measuring

n1 n2 n3 n4 k1 k2 k3 k4 k5

1 5 1 1

1

2

3 ? ?

1 1

2

1 1 1

9 3 3

1

1 1

2

2

2

6 1 1

6 1 1

2

2

1 1

9 3 3

1

3 ? ?

2

0 62 13 10 0 0 0 0

2

Project:

Control and fault reporting

system Switzerland LSS-CH

PLC automation equipment

Specifications