37

saia-pcd.com

PCD

3

Automation stations – Saia PCD3

5

Switch cabinet

components

4

Consumer

data acquisition

3

Dedicated

room controllers

2

Operation

and monitoring

1

Automation

stations

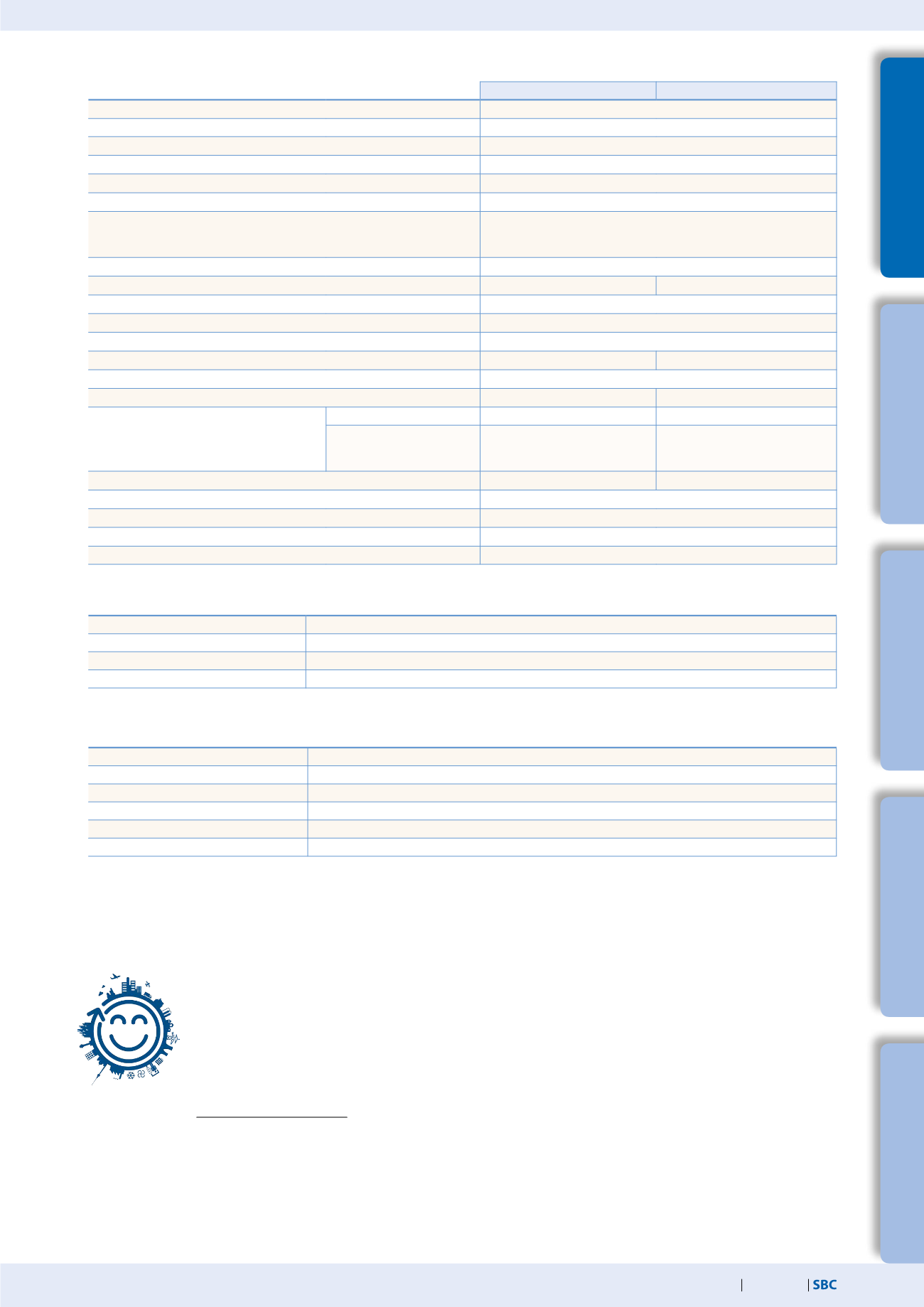

Property

PCD3.T665

PCD3.T666

Number of inputs/outputs

64 in base unit, expandable to 256

I/O module slots

4 in base unit, expandable to 16

I/O modules supported

PCD3.Exxx, PCD3.Axxx, PCD3.Bxxx, PCD3.Wxxx

max. number of RIO stations

128

Protocol for data transfer

Ether S-IO

Ethernet connection

10/100 Mbits, full-duplex, auto-sensing, auto-crossing

Default IP configuration

IP address: 192.168.10.100

Subnet mask: 255.255.255.0

Default gateway: 0.0.0.0

USB interface for configuration and diagnostics

Yes

Program memory

32 kByte

128 kByte

Web server for configuration and diagnostics

Yes

Web server for user pages

Yes

Onboard file system for web pages and data

512 kByte

BACnet® or L

on

W

orks

®

No

No

Onboard interrupt inputs

2

Onboard RS-485 interface

No

Yes

Special modules

for I/O slot 0 only

---

PCD3.F1xx

for I/O slots 0…3

(up to 4 modules)

PCD3.H1xx

---

---

PCD3.H1xx counter

PCD3.F26x DALI

PCD3.F27x M-Bus

S-Web alarming/trending

No

No

Watchdog

No

Real-time clock

No

Software clock (not battery-powered)

yes, synchronised by the Manager

Battery

No

Technical Data

General data

Supply voltage

24 VDC ±20% smoothed or 19 VAC ±15% two-way rectified

Capacity of 5 V bus / +V bus (24 V)

max. 600 mA/100 mA

Ambient temperature

0…+55 °C or 0…+40 °C (depending on mounting position)

Storage temperature

–20…+70 °C

Relative humidity

30…95% RH with no condensation

Mechanical strength

in accordance with EN/IEC 61131-2

In the case of lean automation, it is inefficient to exploit the specified limits or max. number of stations per Manager and

max. number of I/Os per RIO. The following points should be considered:

The load on the RIO Manager increases with the rising number of RIO stations. This has an impact on the overall

application in the RIO Manager.

If there is a large number of RIOs, a sufficiently large volume of PCD media must be reserved on the Manager

for the data transfer.

With the increased number of RIO stations, the build and download process in PG5 is extended accordingly.

Likewise, the start-up behaviour of the Manager or the entire RIO network is proportionately longer.

Recommendation:

20 Smart RIOs per Manager is an effective configuration for efficient and flawless operation and easy commissioning

and support.

The Smart RIOs do not have a battery. In the event of an interruption to the power supply, all the data in the RAM memory

(registers, flags, DBs/text) will be lost. Data and parameters that are remanent must either be transferred by the Manager or stored

in the RIO’s flash file system. If this is not possible, it is recommended to use a normal controller instead of a Smart RIO.

The user programs are stored in the flash memory of the RIOs and are retained in the event of an interruption to the power supply.

System properties/limits and recommendations for lean automation

Smart Automation Manager (master station)

max. 16 RIO stations

PCD3.M2130, PCD3.M2330

max. 32 RIO stations

PCD1.M212x, PCD3.M3330,

max. 64 RIO stations

PCD1.M2160, PCD3.M5340, PCD3.M5540, PCD3.M6x40, PCD7.D457VT5F, PCD7.D410VT5F, PCD7.D412DT5F

max. 128 RIO stations

PCD3.M5560, PCD3.M6560, PCD3.M6860