202

saia-pcd.com

PG5

SCADA

PG5

SCADA

S-IO

Communication & interaction

2.5

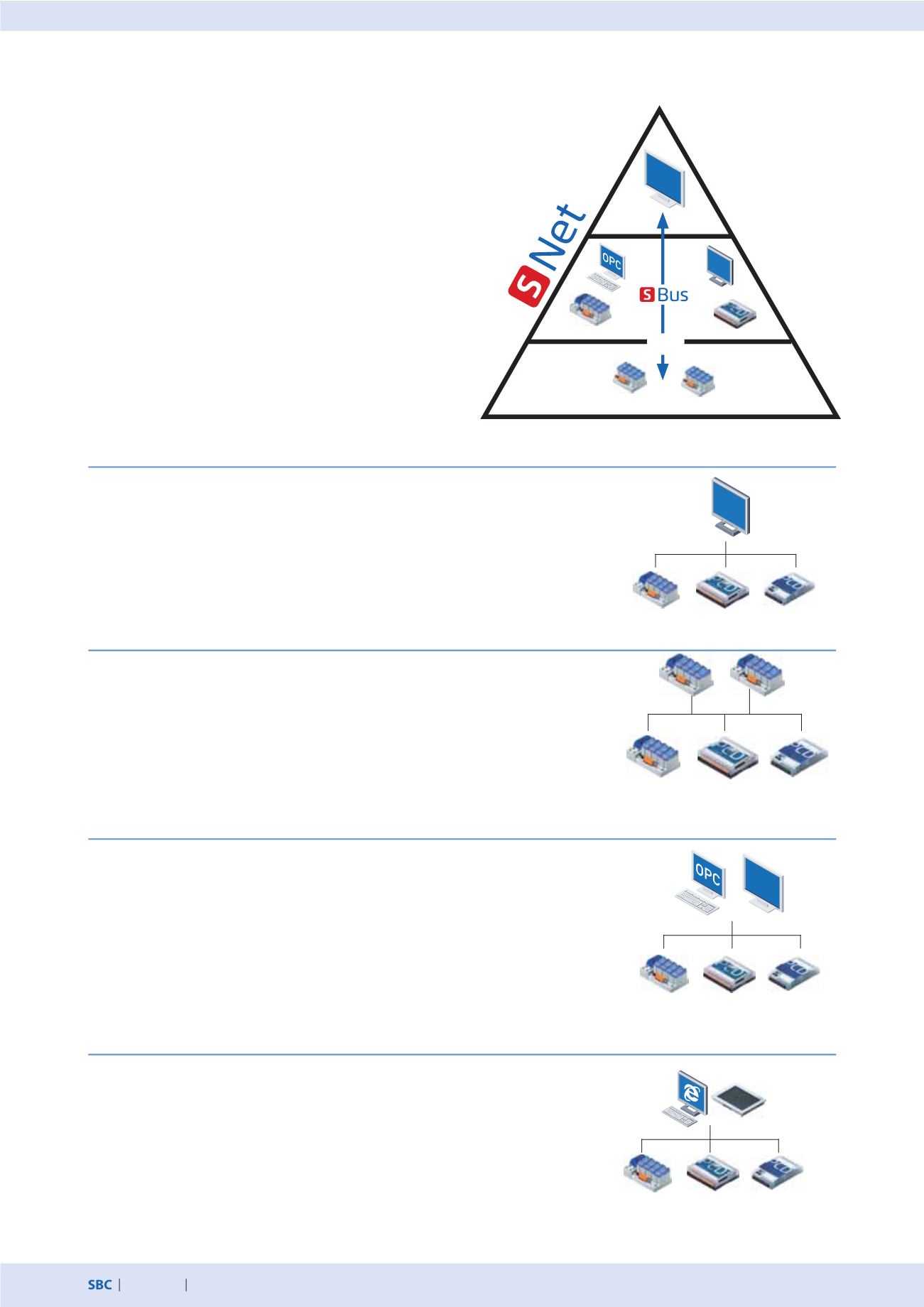

S-Net for communicating between Saia PCD® devices

2.5.1

The basic features of S-Net

S-Net incorporates the S-Bus and S-I/O system protocols for

communicating between SBC devices. Both protocols are optimised

for SBC devices and compared to other standard protocols

(e. g. Modbus) they offer greater functionality and are simpler

and more efficient to use.

S-Bus

supports all services and functions regarding the exchange

of data, programming, commissioning and service of Saia PCD®

controllers. The S-Bus protocol does not depend on the physical

aspects and can be used on Ethernet, USB, Profibus-FDL and serial

interfaces (RS-232, RS-422, RS-485).

The

S-IO

protocol supports the operation of SBC remote I/O stations

with Ethernet (PCD3.T66x) and Profibus (PCD3.T760)

Management layer

S-Net communicating between SBC devices across all layers

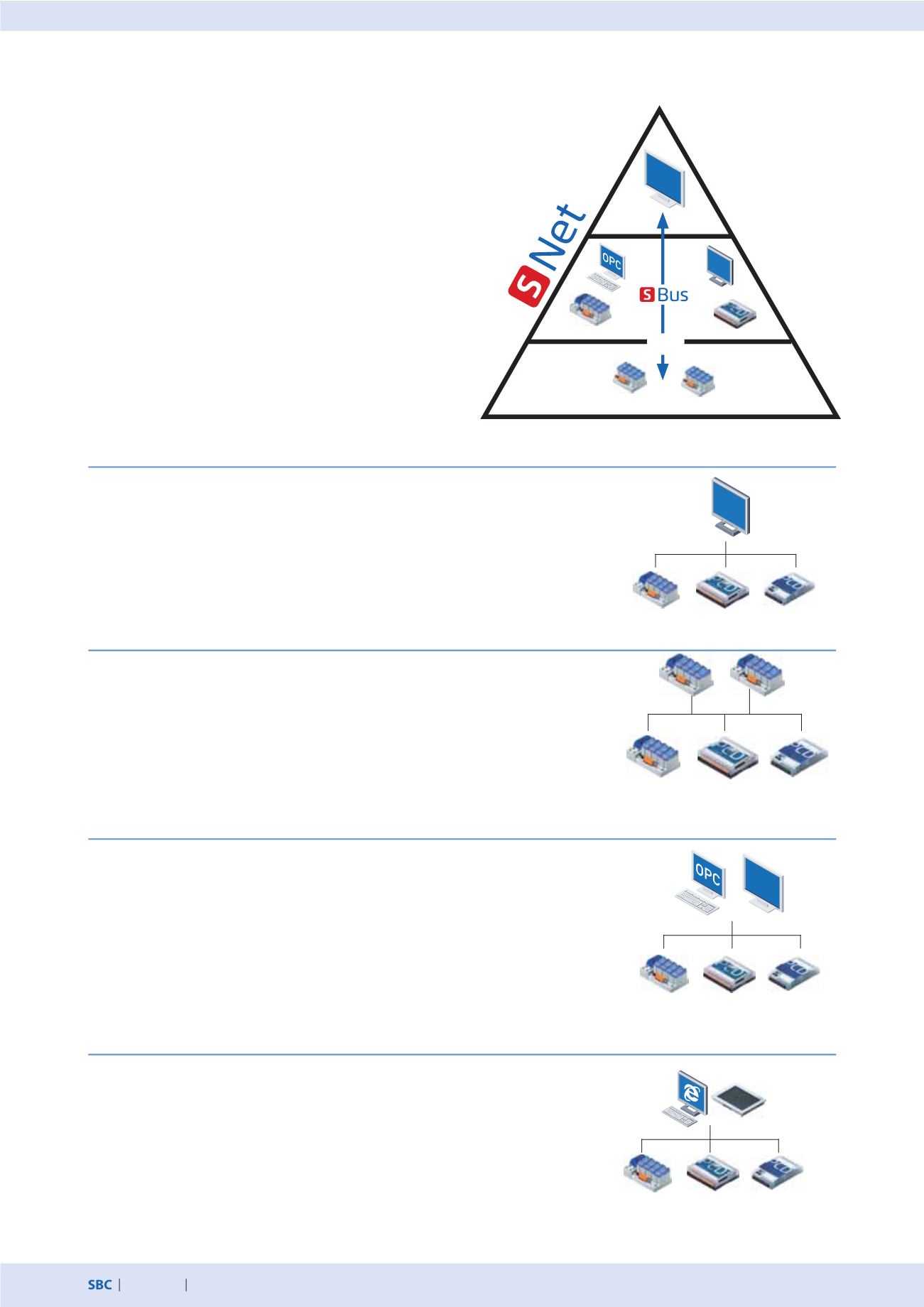

Services and functions using S-Bus

Programming and commissioning

S-Bus is the programming device system protocol. It supports all programming,

commissioning and diagnostic functions.

The programming device is accessed via Ethernet,

USB or serial interfaces.

Exchanging data between PCD controllers via

Ethernet, Profibus or serial interfaces

Connecting to SCADA systems via Ethernet, USB,

Profibus or serial interfaces

Access to the PCD web server is also possible via

USB and Serial interfaces

Visualising with web browsers

S-Bus supports HTTP protocol transmission. This also allows websites to be transmitted

together with “SBC-Web.Connect” via USB and serial interfaces and displayed

on a Windows PC with the standard web browser or a micro-browser web panel.

Visualising with OPC servers and SCADA systems

S-Bus together with an OPC Server or the SBC.Net-Suite supports access (reading

ad writing) to all PCD data with a Windows SCADA system.

Exchanging data between PCD controllers

S-Bus supports the transmission of all PCD media (register, flags, timer/counter,

database and text) and is optimized for the exchange of data between PCD controllers

whereby Ethernet and Profibus allow multi-master operation.

Serial interfaces (RS-232, RS-422, RS-485) enable “single”-Master-Slave mode or S-Bus-

Master-multpile-Slave mode.

Automation layer

Field level