10

saia-pcd.com

Automation stations – the basics

We developed the core of the Saia PCD® operating

systems between 2001 and 2003 as part of a European

cooperation project with Philips and Nokia. We then

expanded the core and focused on an operating system

for advanced, industry-quality measuring, control and

regulation devices. A dedicated operating system for

ICA technology – a control operating system (COS).

Developed in-house and with all aspects fully covered.

Saia PCD® COSinus – Control Operating System

Why COSinus?

The control operating system (COS) ensures that customers’ application software will always operate on

all platforms, is portable across device generations and expandable over several decades. Hardware and

the Windows® programming tools may change, but the customer will not have to modify the application

code. The hardware, software tool and application software can be compared to the sides of a triangle.

If hardware and/or software changes, the angles must adjust for the application software to remain

unchanged. We expanded the abbreviation COS to the name COSinus due to the trigonometric relation-

ships in triangles.

The COSinus operating system always provides the application with the same infrastructure, regardless of the underlying hardware and processor.

The key to this is the Saia virtual machine. It ensures that an application program created with PG5 works on all PCDs across generations.

The main components of Saia PCD® COSinus

1

Multi-tasking kernel:

Abstracts the hardware, incl. I/Os and communication interfaces, provides basic multi-tasking functionality

on which the program processing of Saia PCD® programming is also based.

2

Virtual Saia PCD® machine:

This is the logic machine that executes the PG5 programs. The virtual Saia PCD® code is interpreted

and guarantees that programs are always executed in a consistent manner on different PCD controllers. The three hubs

of the PG5 application program are the following:

Media:

Memory of the virtual PCD machine such as registers, flags, meters, etc.

Program execution:

Program and organisation blocks, text, monitoring, error processing, memory management, etc.

System functions:

Access to the hardware, I/Os, interfaces and drivers

3

Automation Server:

The Automation Server includes widely used web/IT technologies and ensures data exchange between

users and automation solutions with no proprietary hardware or software required.

4

Communication protocols:

Various field and automation protocols such as BACnet®, L

on

, Profibus, Modbus, DALI, M-Bus,

and many others.

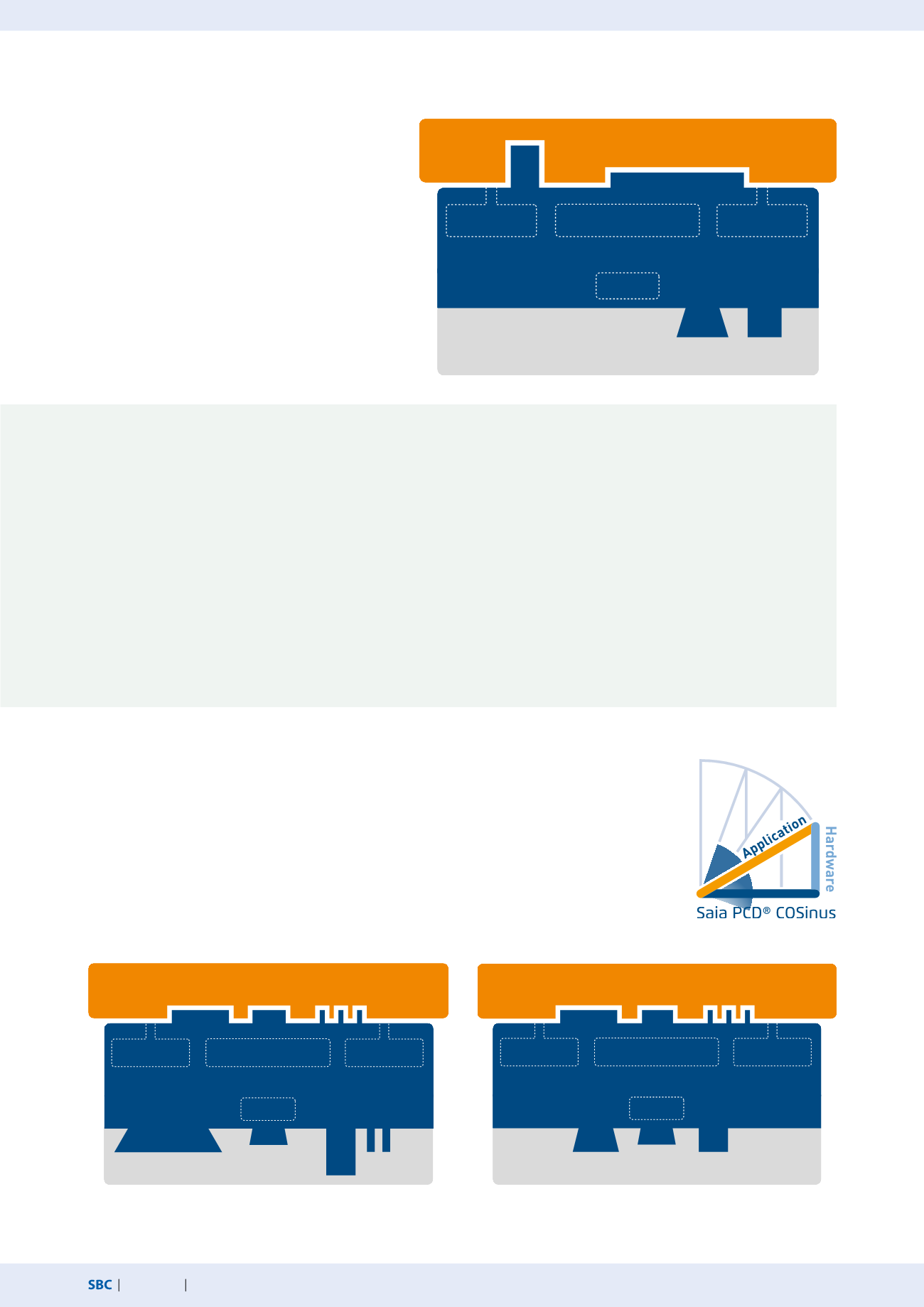

Saia PCD® COSinus connects user programs

and various hardware

User application

Automation Server

Communication

protocols

Virtual Saia PCD® machine

Kernel

COSinus

Hardware type A

User application

Automation server

Communication

protocols

Virtual Saia PCD® machine

Kernel

COSinus

Hardware

User application

Automation Server

Communication

protocols

Virtual Saia PCD® machine

Kernel

COSinus

Hardware type B