269

saia-pcd.com

C

1

Sample Project

Planning guide

2

Product Launch

1

Planning Guide

3

Abbreviations

4

Type Index

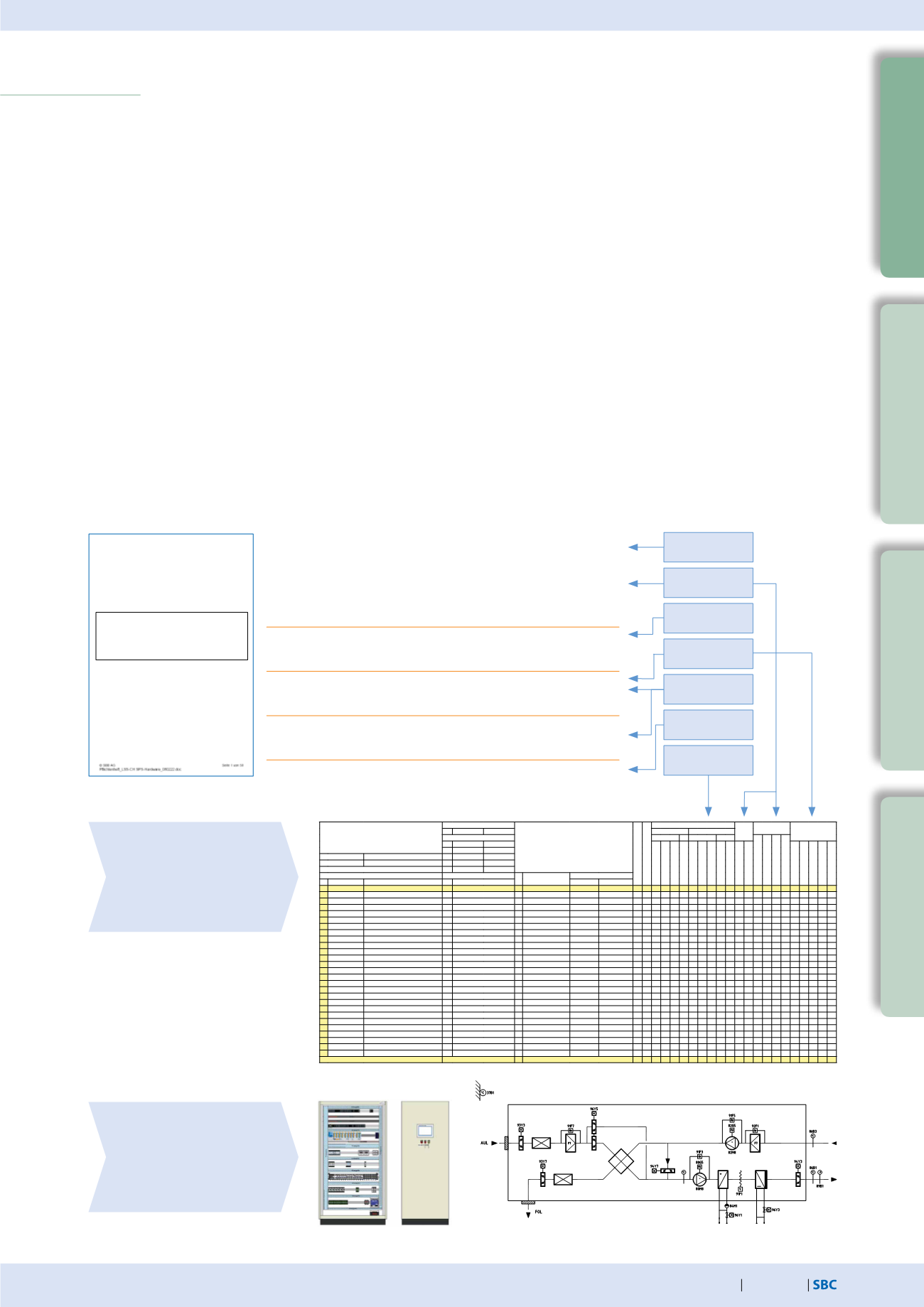

The requirements of technical planners must be considered when selecting the appropriate automation products.

The technical specifications for automation equipment in the following “Standard ventilation” example have been used to

select the most suitable Saia PCD® device family. Other factors such as plant operation are covered in separate chapters.

Procedure / work steps

In accordance with the planning fundamentals (specification), the following steps should be taken when choosing

automation products:

1. Examine the specification requirements for automation equipment to define the selection criteria

2. Define the device family based on the required data points / functions

3. Select the products for communication, expandability and flexibility

4. Define input/output modules

5. Composition of equipment

Planning guide

Plant principle

Display of plant for visual data

point assignment

Indication of mounting location

Data point function list

Selection criteria for

– Device family

– Control functions

– Communication/interfaces

Description:

Two-stage partial air conditioning system with plate

heat exchanger, air heater and air cooler.

Ventilation with manual/override function.

A control cabinet should be included to install the

electrical and automation technology.

Controls:

Flexible, modular and expandable controls

Interfaces:

Basic interfaces – Ethernet / USB energy

measurement M-Bus; expandability option

Expansion

min. 20% expansion reserve

reserve:

Data:

Recording/storage of operational data

Specifications

1.

Examine the specification requirements

Requirement arising from the specifications

Selection criteria

In-/outputs

Modularity

Communication

Mounting

location

Manual

operation

Expandability

Data memory

Project:

Control and fault reporting

system Switzerland LSS-CH

PLC automation equipment

Specifications

Erstellt

Allgemeines:

Anschlussleistung (kW)

Hardwarefunktionen

PhysikalischeE/A-Funktionen Not-

bedie-

nung

Bedien-

Funktionen Kommunikative

E/A-Funktionen

Bearb:SP Datum:1.3.11

Ausgänge

Eingänge

Geändert:

BA AA BE AE

Grafik/Anlagenbild

DynamischeEinblendung

Ereignis-Anweisung

NachrichtanexterneStelle

a Bearb:

Datum:

Dauer-Schaltbefehl

Impuls-Schaltbefehl

PWM/3-Punkt-Stellbefehl

StetigerStellbefehl

Betriebs-/Statusmeldung

Störung/Alarm

Zählen

Messwert aktiv

Messwert passiv

Schalten/Stellen

Anzeigen

Schalten

Stellen/Sollwert

Melden

Zählen

Messen

b Bearb:

Datum:

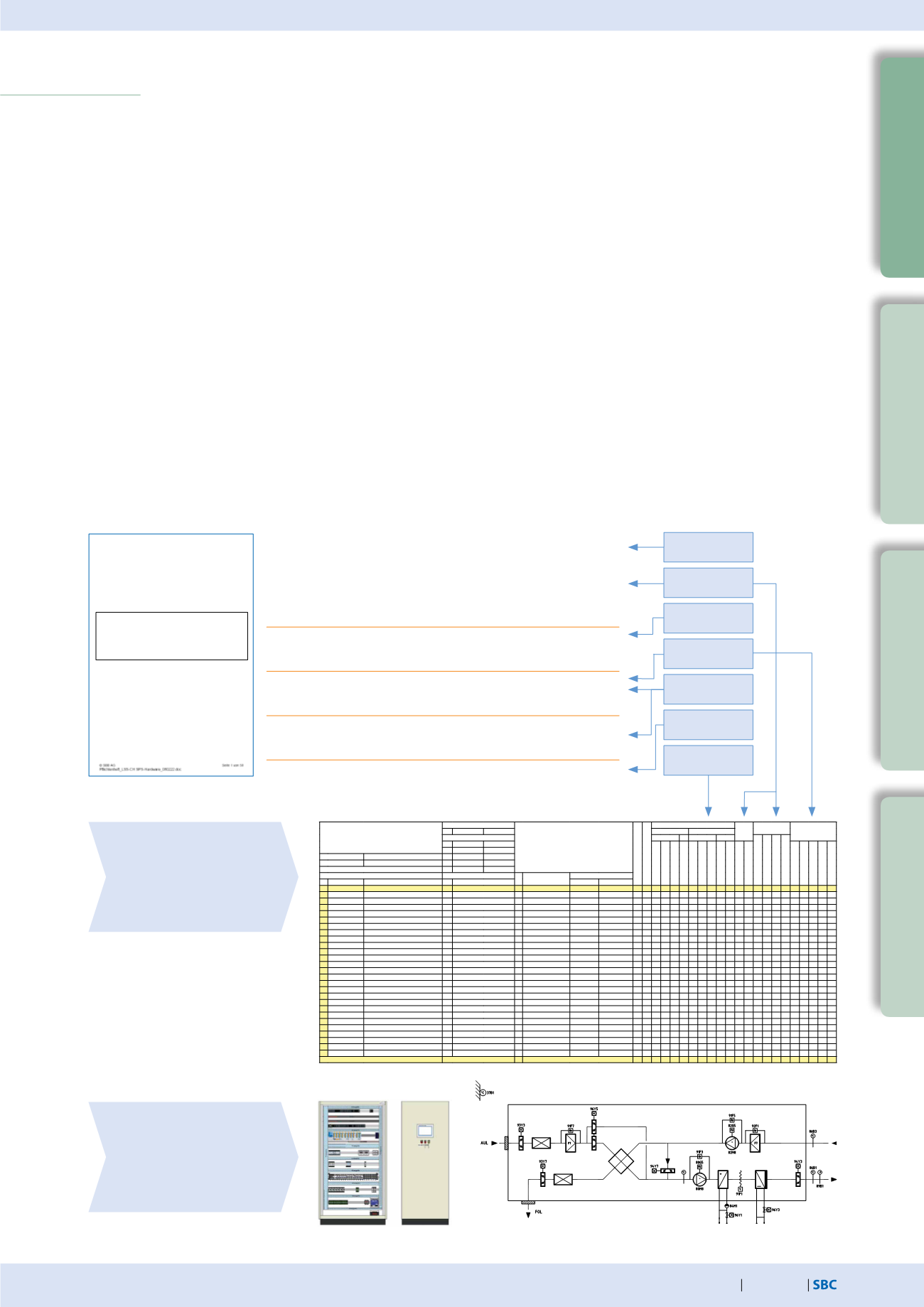

Projekt-Nr 101726 Objekt:ZimmerG530

c Bearb:

Datum:

Anlagen-Nr: LA03 Anlage: LüftungNebenräume

d Bearb:

Datum:

Anlage-Ort:

Aussen, 6.OG

e Bearb:

Datum:

Schaltschrank

SLU01

Typ

Anzahl

Bemerkungen

Feldgeräte

Nr.Adresse

Text

CodBeschreibung

Hersteller

Typ

a

b

c1

c2

d

e

f1

f2

g h 1 2 3 4 5 6 7 8 9 1 2 n1 n2 n3 n4 k1 k2 k3 k4 k5

LA03

Anlagenschalter

a11 Anlageallg.:Auto-Aus-Ein 1

0 3

2 1

1 5 1 1

a21Brandalarm

1

1

1

1

AULTemperatur (Kanal)

c06MessungpassivmitRegler 1

1

2

AULKlappe

d02StellantriebZu/Aufmit 1Endsch 1

1

1

3 ? ?

Druckdifferenzschalter

I46 Filterwächter

1

1

1

1 1

WRGBypassKlappe

d21Stellantrieb stetig

1

1

1

2

Frostschutz

l41 Frostwächter

1

1

1

1

1 1 1

ZULVentilator

l05 Ventilatorm.FU,o.Umgehung 1

5 1 1

1

4

2 3

9 3 3

1

Druckdifferenzschalter

l46 Filterwächter

1

1

1 1

LEVentil

d21Stellantrieb stetig

1

1

1

2

ZULTemperatur (Kanal)

c06MessungpassivmitRegler 1

1

2

ZULDruckfühler (Kanal)

c06MessungpassivmitRegler 1

1

2

ZULBSK

l61 Brandschutzklappemotorisch 1

1 1

2 1

1 2

6 1 1

ABLBSK

l61 Brandschutzklappemotorisch 1

1 1

2 1

1 2

6 1 1

ABLTemperatur (Kanal)

c06MessungpassivmitRegler 1

1

2

ABLDruckfühler (Kanal)

c06MessungpassivmitRegler 1

1

2

Druckdifferenzschalter

l46 Filterwächter

1

1

1 1

ABLVentilator

l05 Ventilatorm.FU,o.Umgehung 1

5 1 1

1

4

2 3

9 3 3

1

FOLKlappe

d02StellantriebZu/Aufmit 1Endsch 1

1

1

1

3 ? ?

FOLTemperatur (Kanal)

c06MessungpassivmitRegler 1

1

2

Summen

TotalphysikalischeE/A:43

Totel kommunikativeE/A:0

10 6 9 0 0 4 8 16 0 0 6 10 11 0 62 13 10 0 0 0 0

2

Data point list