Programmable Controller SBC PCD3 system

-

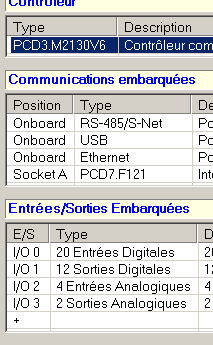

PCD3.M2xxx Compact CPU base units

with onboard I/Os and in case of the Wide Area Controller modem

Onboard interfaces: USB, RS-485, Ethernet, (Modem)

-

PCD3.M3xxx CPU base units

with 4 I/O module slots.

Onboard interfaces: USB, RS485, Ethernet

-

PCD3.M5/6xxx CPU base units

with 4 I/O module slots.

Onboard interfaces: USB, RS232, RS485, Ethernet, Profibus, CAN Basic.

Slots for memory modules and battery module

-

PCD3.M5/6x60 CPU base units (Power CPU)

with 4 I/O module slots.

Onboard interfaces: USB, RS232, RS485, Ethernet, Profibus, CAN Basic.

Slots for memory modules and battery module

Link to PCD3 CPU power CPU page

-

PCD3.M6860/6880 CPU base units (Power CPU) with 2 independent Ethernet ports

with 4 I/O module slots.

Onboard interfaces: USB, RS232, RS485, Ethernet, Profibus.

Slots for memory modules and battery module

Link to PCD3 CPU double Ethernet CPU page

-

The PCD3.M6893 CPU is desiged for critical applications and allows high-level language programming in accordance with IEC 61131-3 including object-oriented methods and Cyber security.

The PCD3.M6893 base units (Power CPU) with 2 independent Ethernet ports and 4 I/O module slots.

Onboard interfaces: USB, USB Host, RS485, Ethernet, CAN

Slots for aditional RS485 module and uSD memory module

Link to PCD3.M6893 CPU page

PCD3 / Mxxx

-

How to know whether the circuit board of the PCD is fitted with a Swissbit micro-SD memory card? (FAQ #102070)

It is only possible to determine whether the PCD's circuit board is fitted with a Swissbit micro-SD memory card by visual inspection.

The attached document describes how to know whether the circuit board of the PCD is fitted with a Swissbit micro-SD memory card.

-

How to copy csv-Files and Webeditorproject files which are stored on the Intflash of a PCD, if you are replacing an internal micro-SD memory card which is used on the circuit board of the PCD? (FAQ #102069)

The attached document describes how to proceed if you want to copy csv-Files (e.g., from HDLog) and Webeditorproject files which are stored on the Intflash of a PCD.

This could be useful if you are replacing an internal micro-SD memory card which is used on the circuit board of the PCD and you want to re-use the files stored on the old micro-SD memory card.

-

What is stored on the micro-SD memory card which is used on the circuit board of the PCD? (FAQ #102068)

Newer PCD types and newer PCD7.D4xx devices have micro-SD memory card (uSD) on the PCB (printed circuit boards)

The following data’s are stored on the this uSD card on the PCD’s PCB:

- Firmware for the PCD

- Device configurator settings (PG5)

- Application program done with PG5

- Webeditor 8 project (PG5)

- DATA (e.g HDLog) created by the application program in runtime

- Setup, Calibration (PCD7.D443, PCD7.D450, PCD.D470)

- Program Backup on internal Flash

-

How can the micro SD memory card on the circuit board of a PCD controller be replaced? (FAQ #102067)

In some cases, it is necessary to replace the micro-SD memory card (uSD) of the PCD.

This FAQ describes how to replace the micro-SD memory card (uSD) which is mounted on the PCD controller's PCB (printed circuit boards)

The attached .pdf describes how to replace the micro-SD memory card (uSD) used on the PCB of the PCD

-

Why are the inputs and outputs of a PCD3 systems not switched on and off correctly, or switched on and off randomly, or the I/O status not detected correctly in the PLC? (FAQ #102063)

The problem may be related to a loose contact on the PCD3.K010 connectors used to connect the PCD3.M/Txxx CPU's and the PCD3.Cxxx expansion modules.

In this case, various error patterns may occur, such as

- - If an input is set to 1, then several inputs are set to 1 at the same time.

- - If an output is set to 1 in the application program, then the output is not set on the output module.

- - The status of the inputs is not correctly recognised in the application program.

The affected PCD3.K010 modules have a manufacturing date of 2028 (year 2020, week 28).

If the symptoms described above occur and a PCD3.K010 module with fabrication date 2028 is used, replace the PCD3.K010 module with a new PCD3.K010 module.

Order new PCD3.K010 modules and create an RMA request with the error description and the remark: CRABBMS-430 and select the option 'Advanced replacement'.

The date of manufacture can be seen on the white sticker on the PCD3.K010.

-

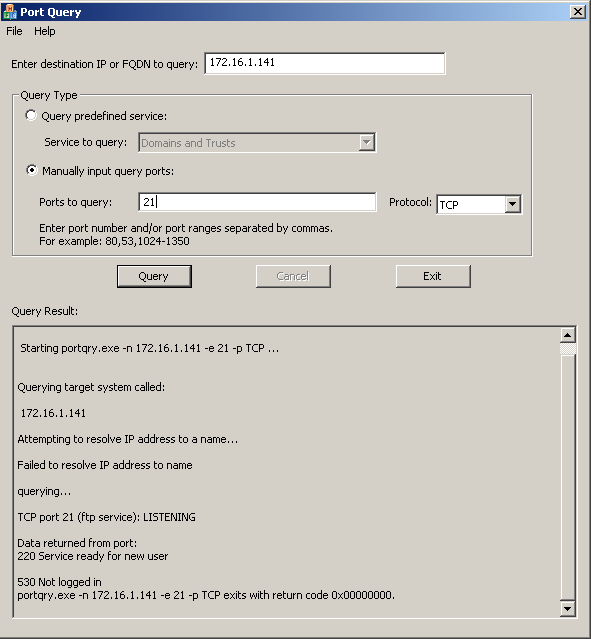

It's possible to connect SBC PCD's directly to the internet? (FAQ #102060)

Yes it’s possible to connect a PCD directly to the internet, but you have to protect your PCD against unauthorised access or cyber-attacks.

To protect the PCD against unauthorised access or cyber-attacks, it’s imperatively needed to take some protective measures.

Information about protective measures can be found on the support hp

If you need a PCD with cyber security levels SL3+ and based on ANSI ISA 62443 then checkout our PCD3.M6893 (QronoX PCD), this PCD was developed for cybersecure applications.

Information's can be found here.

-

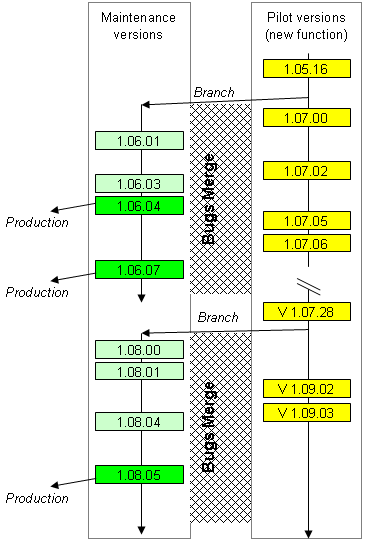

What are the differences between the COSinus firmwares FW 1.28.11 and FW 1.28.51? (FAQ #102058)

In January 2024:

the COSinus BACnet FW 1.28.59 was put on the support homepage.In April 2022:

the COSinus FW 1.28.51 was introduced into production for the systems:- PCD1.M0xx0/M2xx0, PCD2.M4x60, PCD3.Mxx60 and PCD3.M6880.

In February 2019:

the COSinus FW 1.28.37 was released as maintenance version for the systems:- PCD1.M0xx0/M2xx0, PCD2.M4x60, PCD3.Mxx60, PCD3.M6880 and PCD3.T665/T666/T668.

In June 2017:

the COSinus FW 1.28.16 was introduced into production for the systems:- PCD1.M0xx0/M2xx0, PCD2.M4x60, PCD3.Mxx60, PCD3.M6880 and PCD3.T665/T666/T668.

the BACnet and LonIP FW 1.28.51/1.28.59 was put into production, which do support the BACnet Revision 14.

To support the BACnet Revision 9 it's necessary to use the PCD and the BACnet FW 1.26.xx.Attention:

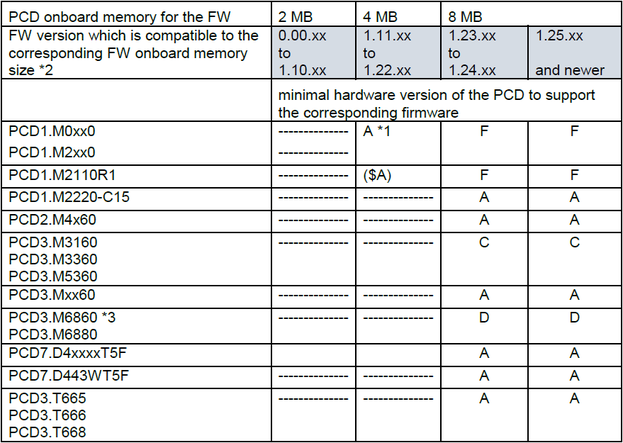

The firmware 1.28.xx or later can be used only on the following PCD's with 8 MB onboard firmware memory:

PCD1.M0xx0/M2xx0, PCD2.M4x60, PCD3.Mxx60, PCD3.M6880 and PCD3.T665/T666/T668

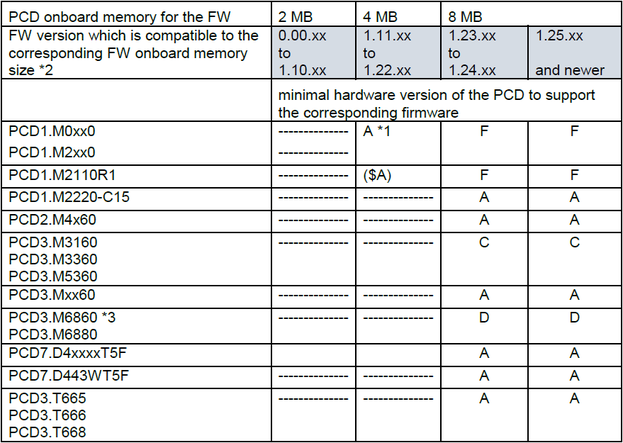

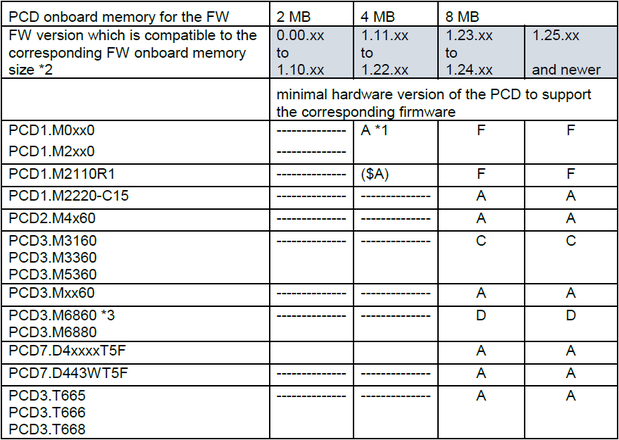

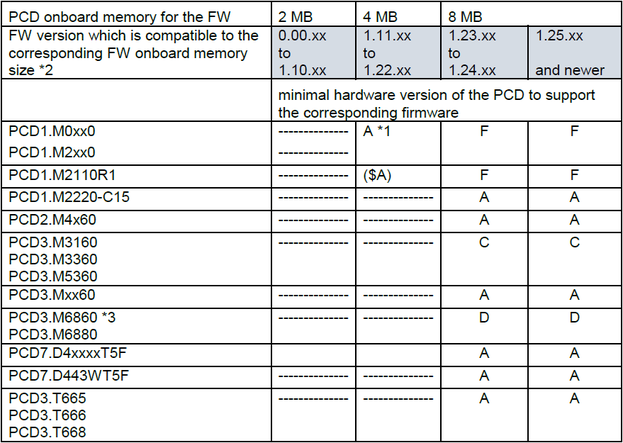

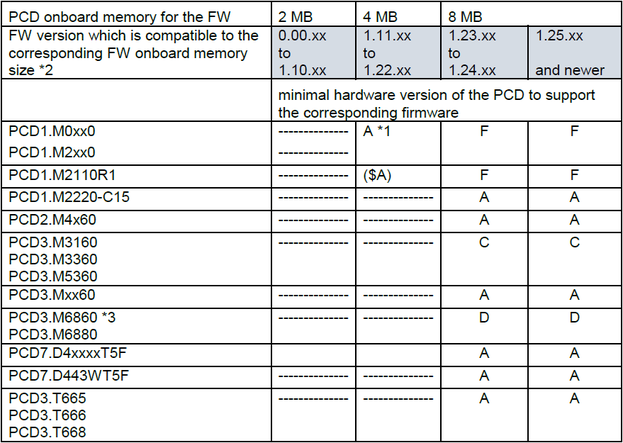

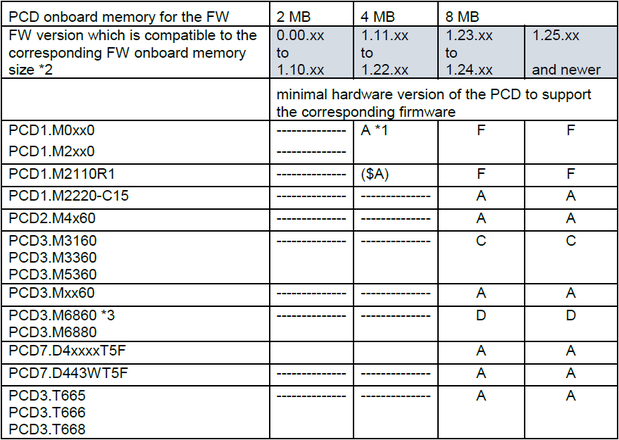

The table below does show the hardware dependencies in relation with the COSinus firmware versions

Do use at least the PG5 firmware downloader version 2.1.311 or newer (included in PG5 patch 2.1.311 or newer) to prevent the loading of the FW 1.24.xx, 1.26.xx or newer to a not compatible PCD

Firmware 1.28.59 (only BACnet firmware) (January 2024)

Main corrections

- BACnet: MI/MO/MV objects, invalid values for Alarm_Values and Fault_Values are rejected

- BACnet: BI/BV/BO objects, present value of can only be 0 or 1

- BACnet: COMMAND object, present value writing returns an error if bigger that the number of actions

- BACnet: Trendlog objects, property value check is done according to specifications

- BACnet: Limit COV subscription to 3000 and send PDU-Error if length of response is too big

- BACnet: Disable I-Have response when state is disable / disable-init

- BACnet: Calendar Object Date List, don’t allow wild card in this property entries

- BACnet: writing invalid array to Array properties returns correct Error code

- BACnet: Pulse Converter Object, send out-of-range PDU-Error if count processing is < 0

- BACnet: Controller goes to HALT with SWTO error

- BACnet: MS/TP Controller goes to HALT with SWTO error

- BACnet: Schedule accepts Sundays in Week and Day

- BACnet: GetEnrollmentSummary: correct reply if list is empty

Firmware 1.28.51 (April 2022)

Main corrections

- All PCD’s: Saia PCD Modbus diag does not work if diag flag > 9999

- All PCD’s: SNTP and hardware RTC is diverging from more than 2 seconds, then History message ‘RTC Fail error’ is generated

- All PCD’s: SNTP Time synchronization does not work with DHCP

- All PCD’s: E-Mails send from PCD could contain unwanted characters like 0 or others

- All PCD’s: S-Monitoring values for S-Monitoring bar graphs are sometime wrong

- All PCD’s: S-Monitoring Year graph scaling displayed wrongly

- All PCD’s: TCP, open data mode protocol, communication is blocked after rejection of 32 connections

- All PCD’s: LonIP CSF is locked when an error occurs

- PCD2.M45x0: SRXM does not support FB parameters as operand 3 and 4 for source and destination

- PCD1.M2220-C15: Watchdog LED does not follow Relay when PCD goes in STOP or HALT

- PCD3.M6880: Data exchange between CPU 0 and CPU 1 does not work reliable if STL instruction is used

- BACnet: Calendar state not updating after add/remove list element service

- BACnet: Exception schedule writing to certain array index fails

- BACnet: Schedule crashes with SWTO error

- BACnet: MS/TP client properties are not written if many values change simultaneously

- BACnet: Problem reliability & out of service, reliability is not written when oos is high

- BACnet: Web CGI commands to read BACnet platform tags like ..AddFW,Version,BACnet don’t work

- BACnet: Web scheduler/calendar templates do not work

- BACnet: PCD3.M6860 no BACnet communication on ETH2 if router is used

- BACnet: Rev 4 not working with Name based Client

- BACnet: Rev14 does not allow high limit value below 5 on analogue input

Firmware 1.28.37 (February 2019)

New features

- All PCD’s: FW extension to close all open FTP connections

- BACnet: Calendar objects have been extended with a synchronization mode. Each server calendar object can be configured as Slave or Master calendar

- BACnet: New mappings for alarming counters have been added to Notification-Class objects.

- BACnet: The PCD will now accept AcknowledgeAlarm service requests, which use complete wildcards as timestamps.

Main corrections

- All PCD’s: On S-Bus data mode, if S-Bus CRC contains a S-Bus DLE as last character then S-Bus telegram is incorrect and not accepted from S-Bus recipient. (Since FW 1.28.20)

- All PCD’s: Not all bytes are transmitted when working with MC4 or MC5 mode on F2xxx module

- All PCD’s: RS485 driver keep holding bus after a while

- All PCD’s: Http request ‘is modified’ is not handled correctly on the PCD Web-Server which lead to the effect that web project is not loaded correctly on the browser

- All PCD’s: PCD can crash when breakpoint is updated during conditional RUN

- All PCD’s: PCD can crash on download in run since FW 1.28.27.

- All PCD’s: PCD can crash on download in run when Graftec is used

- All PCD’s: PCD crashes when using browser to access the default page of PCD with "Display Root Content Enabled = YES"

- All PCD’s: RCOB does not start COB when it was stopped before with SCOB

- All PCD’s: Profibus communcation using onboard FDL port. The FCS test for SD2 telegram was not implemented correctly.

- All PCD’s: When S-Bus IP Nodelist is used it’s possible that the communication using nodes does no more work after execute a download in run

- All PCD’s: XOB parameter as Registers does not work if 16bit addressing was used

- All PCD’s: LonFT10: SNVT_obj_status and SNVT_obj_request can be used in user profiles

- PCD3.Mxx60, PCD3.T6xx, PCD1.M2xx0, PCD2.M4x60: usage of I/O media mapping slows done the cycle time 2 times in comparison to FW 1.26.xx

- PCD2.M4x60: Download LonIP config not possible

- PCD2.M4x60: RTC gets sometime corrupted data when PCD7.F7500 is used on PCD2.M4x60

- PCD2.M4x60: RTC Time is wrong after several days of run

- PCD7.D443WTxR: uBrowser use alphapad.teq even if screen is rotated by 90°

- PCD7.D443WT5R: History entry Memory ‘Lost -1’ written in the History

- BACnet; Event Enrolment does not work correctly with external reference devices.

- BACnet; When using BACNet Webvisu the memory used increase each time the scheduler is edited.

- BACnet; PCD crash when BACnet Webvisu edit scheduler.

- BACnet; BACnet WebVisu does not display correct value for the WeeklySchedule value.

- BACnet; ACK Required bit in notification message is not set according to the related NV ack_required bits

- BACnet: The PCDAlarmStatus mapping property does not work correctly.

- BACnet: Mappings, which changed to the value 0 directly after a program download, are not updated correctly on the BACnet property.

- BACnet: The Priority-Array mapping does not work correctly after startup.

- BACnet: Initialization of Puls converter count with input reference gives error

- BACnet: Fix issue with weekly scheduler.

- BACnet: Fix issue with WeekNDay entries

- BACnet: The Restore functionality over BACnet does not work, when the PCD has been reset over factory reset.

- BACnet: The Action property in the command object does not handle NULL datatype and priority entries correctly, if they are used in the ActionCommand. Additionally, the Action property can now be read via index.

- BACnet: Priority_Array entry 16 will be overwritten on startup with the last Present_Value mapping

- BACnet: Out of Service -> Value for PV overridden after reboot by Input ref

- BACnet: The Log_Buffer to csv conversion for trend-log objects does not skip time change entries

- BACnet: Unmapped Priority-Array property array entries are not stored persistent

- BACnet: BACnet configuration on the PCD is not deleted when "unlinked" from PG5

- BACnet: Change Client Time_Of_Restart mapping to Unix time

- BACnet: Client mapping - Threshold is not implemented correctly

- BACnet: Mapped Reliability properties within analogue objects does interfere with the objects functionality. When the Reliability is mapped, the mapping has not full control over the property value.

- BACnet: The program download fails, when the BACnet config contained notification-class objects with event-counter mappings

- BACnet: BACnet Trend-Log(-Multiple) data can’t be retrieved as csv data

- BACnet: The SubscribeCOVProperty service can’t be executed on complete Priority_Arrays

Firmware 1.28.16 (June 2017)

New features

- All PCD's: When push button is pressed while power on then do not update FW from FS in order to execute a delete all.

- PCD1.M0xx0/M2xx0, PCD2.M4x60, PCD3.Mxx60, PCD3.M6880 and PCD3.T665/T666/T668:

Enhancement for HTTP server to transparently support sending compressed files.

Main corrections

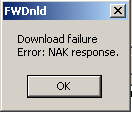

- All PCD's SBUS parity mode, correction when NAK character is received as first byte of response.

- All PCD's: When download new Ethernet-RIO Program with the option ‘Delete all backups’ it can happen that the RIO is not commission and no goes no more in ‘data exchange mode’ until the PCD reboots.

- All PCD's: When RIO name is not in upper case the RIO file is not updated until a restart is executed.

- All PCD's: When RIO file is downloaded with download changed RIO file then RIO file is not sent to RIO until a restart is executed.

- All PCD's: Ethernet Frame Padding Information Leakage fixed (CVE-2017-9628)

- All PCD's: The Modbus CSF CloseSRPort does not free the port then a open/SASI call give an error and the port does not work.

- PCD1.M2xx0 PCD1.M22x0 PCD2.M4x60: PCD can crash while power down when XOB 0 is programmed.

- PCD1.M2xx0 PCD1.M22x0 PCD2.M4x60: MC0 mode with start/stop flag working again.

- PCD7.D443WT5R: Alarming does not work since 1.28.00 FW.

- PCD7.D443WT5R: When watchdog timeout occurs PCD7.D443WT5R does't reboot and stays locked.

Firmware 1.28.11 (Arpil 2017)

New features

- All PCD's: Support of BACnet Revision 14

Main corrections

- All PCD's: Various Open Data Mode fixes: Read Timeout enhancement, Client Connection timeout and Client Keep alive with anonymous port issue fixed

- All PCD's: Modbus RTU on all ports but specially on the F2xx module has been corrected to handle the response timeout processing in the case that the response is just occurring at the moment of the timeout.

- All PCD's: Battery status shows FAIL also if battery module is missing.

All PCD's: Various minor issues fixed - PCD1.M2xx0 & PCD3+: 38400/115200 baud settings adjustment

- PCD2.M4x60: PCD7.F7500 initialization

-

On a PCD2.M4560 or PCD3.M5560, why the measured PT100 temperature values are not correct if the PT100 sensors are connected to PCD2.W220Z18 or PCD3.W220Z18 modules? (FAQ #102052)

If the PCD2/3.W220Z18 card is plugged in to a ‘Power PCD‘ or a PCD2.C1000 or PCD2.C2000 and if all 8 analog inputs channels of the PCD2/3.W220Z18 module are connected to 8 PT100 sensors then the measured PT100 temperature values of the 8 channels are not correct.

‘Power PCD’s’ are:

- PCD1.M2x20, PCD1.M2160, PCD1.M2220-C15

- PCD2.M5540, PCD2.M5440, PCD2.M4160, PCD2.M4560

- PCD3.Mxx60

To solve the issue, use and connect only up to 7 PT100 sensors to the PCD2/3.W220Z18 or do use a PCD2/3.W350 module, if all 8 PT100 are needed.

On the ‘old’ PCD’s like PCD2.M170 or PCD3.M5540 the PCD internal power supply V+ was at 24V

On the ‘new’ ‘Power-PCD’s’ and the PCD2.C1000 and PCD2.C2000 the V+ is 16,5V

The electrical design of the PCD2/3.W220Z18 was done in that the way, that the internal power V+ of 24V was required to handle all 8 PT100 channels.

Since the ‘Power PCD’s’ and the PCD2.C1000/C2000 have a V+ of 16,5V the driver on the PCD2/3.W220Z18 don’t have enough power to handle all 8 PT100 signals correctly.

To solve the issue, use and connect only up to 7 PT100 sensors to the PCD2/3.W220Z18 or do use a PCD2/3.W350 module, if all 8 PT100 are needed.

-

Why on a PCD3.M5/6xxx or a PCD2.M45xx the battery LED is switched on and the battery error message is activated in the application program after a new battery was inserted? (FAQ #102039)

The battery voltage is checked in the battery module for undervoltage and overvoltage.

New batteries have a too high voltage which causes the overvoltage limit to be exceeded.

Solution:

With the FBox 'PCD3.BAT0', selectable from the ‘System information’ family it is possible to switch off the overvoltage limit check on the battery module to prevent the battery LED from being switched on and the battery error message in the application program from being activated if the battery voltage is above the overvoltage limit.

The battery voltage check is performed in the battery module and the changes made by the FBox 'PCD3.BAT0' are stored in the battery module and not in the PCD3.M5/6, PCD2.M45xx.

As all information concerning the overvoltage limit check are stored in the battery module, it is possible to make the modifications in one PCD 'A' and after the modification, to insert the battery module in another PCD 'B'.

Battery modules with hardware version < C have a factory default battery undervoltage and overvoltage check.

Battery modules with hardware version >= C have the battery undervoltage test function ex works.

The battery overvoltage is not checked.After the FBox 'PCD3.BAT0' has deactivated the overvoltage limit check, modification 8 is activated on the battery module.

Picture shows a battery module with hardware version A and modification 1 and 3

The modification number is displayed also on PG5 Online configurator, hardware information.

After the usage of the FBox 'PCD3.BAT0' the following information is visible on the PG5 hardware information. (Modification 8 was added)

Modification number 8 is only activated for this purpose 'Overvoltage limit check disabled'.

After changes have been made with the FBox 'PCD3.BAT0', the 24VDC power supply to the PCD must be switched off and on again so that the changes relating to the battery LED, battery error message in the application program and the update of the modification number in the hardware information can be adopted.

More information are available on the online FBox help.

Overview battery module hardware version, modification, under- and overvoltage test.

The FBox library ‘SBC Maintenance’ which includes the 'PCD3.BAT0' FBox can be loaded from this FAQ, over the PG5 update manager and will be installed automatically with newer PG5 versions.

-

What are the differences between the COSinus firmwares FW 1.28.11 and FW 1.28.51? (FAQ #102010)

In April 2022:

the COSinus FW 1.28.51 was introduced into production for the systems:- PCD1.M0xx0/M2xx0, PCD2.M4x60, PCD3.Mxx60 and PCD3.M6880.

In February 2019:

the COSinus FW 1.28.37 was released as maintenance version for the systems:- PCD1.M0xx0/M2xx0, PCD2.M4x60, PCD3.Mxx60, PCD3.M6880 and PCD3.T665/T666/T668.

In June 2017:

the COSinus FW 1.28.16 was introduced into production for the systems:- PCD1.M0xx0/M2xx0, PCD2.M4x60, PCD3.Mxx60, PCD3.M6880 and PCD3.T665/T666/T668.

the BACnet and LonIP FW 1.28.16 was put into production, which do support the BACnet Revision 14.

To support the BACnet Revision 9 it's necessary to use the PCD and the BACnet FW 1.26.xx.Attention:

The firmware 1.28.xx or later can be used only on the following PCD's with 8 MB onboard firmware memory:

PCD1.M0xx0/M2xx0, PCD2.M4x60, PCD3.Mxx60, PCD3.M6880 and PCD3.T665/T666/T668

The table below does show the hardware dependencies in relation with the COSinus firmware versions

Do use at least the PG5 firmware downloader version 2.1.311 or newer (included in PG5 patch 2.1.311 or newer) to prevent the loading of the FW 1.24.xx, 1.26.xx or newer to a not compatible PCD

Firmware 1.28.51 (April 2022)

Main corrections

- All PCD’s: Saia PCD Modbus diag does not work if diag flag > 9999

- All PCD’s: SNTP and hardware RTC is diverging from more than 2 seconds, then History message ‘RTC Fail error’ is generated

- All PCD’s: SNTP Time synchronization does not work with DHCP

- All PCD’s: E-Mails send from PCD could contain unwanted characters like 0 or others

- All PCD’s: S-Monitoring values for S-Monitoring bar graphs are sometime wrong

- All PCD’s: S-Monitoring Year graph scaling displayed wrongly

- All PCD’s: TCP, open data mode protocol, communication is blocked after rejection of 32 connections

- All PCD’s: LonIP CSF is locked when an error occurs

- PCD2.M45x0: SRXM does not support FB parameters as operand 3 and 4 for source and destination

- PCD1.M2220-C15: Watchdog LED does not follow Relay when PCD goes in STOP or HALT

- PCD3.M6880: Data exchange between CPU 0 and CPU 1 does not work reliable if STL instruction is used

- BACnet: Calendar state not updating after add/remove list element service

- BACnet: Exception schedule writing to certain array index fails

- BACnet: Schedule crashes with SWTO error

- BACnet: MS/TP client properties are not written if many values change simultaneously

- BACnet: Problem reliability & out of service, reliability is not written when oos is high

- BACnet: Web CGI commands to read BACnet platform tags like ..AddFW,Version,BACnet don’t work

- BACnet: Web scheduler/calendar templates do not work

- BACnet: PCD3.M6860 no BACnet communication on ETH2 if router is used

- BACnet: Rev 4 not working with Name based Client

- BACnet: Rev14 does not allow high limit value below 5 on analogue input

Firmware 1.28.37 (February 2019)

New features

- All PCD’s: FW extension to close all open FTP connections

- BACnet: Calendar objects have been extended with a synchronization mode. Each server calendar object can be configured as Slave or Master calendar

- BACnet: New mappings for alarming counters have been added to Notification-Class objects.

- BACnet: The PCD will now accept AcknowledgeAlarm service requests, which use complete wildcards as timestamps.

Main corrections

- All PCD’s: On S-Bus data mode, if S-Bus CRC contains a S-Bus DLE as last character then S-Bus telegram is incorrect and not accepted from S-Bus recipient. (Since FW 1.28.20)

- All PCD’s: Not all bytes are transmitted when working with MC4 or MC5 mode on F2xxx module

- All PCD’s: RS485 driver keep holding bus after a while

- All PCD’s: Http request ‘is modified’ is not handled correctly on the PCD Web-Server which lead to the effect that web project is not loaded correctly on the browser

- All PCD’s: PCD can crash when breakpoint is updated during conditional RUN

- All PCD’s: PCD can crash on download in run since FW 1.28.27.

- All PCD’s: PCD can crash on download in run when Graftec is used

- All PCD’s: PCD crashes when using browser to access the default page of PCD with "Display Root Content Enabled = YES"

- All PCD’s: RCOB does not start COB when it was stopped before with SCOB

- All PCD’s: Profibus communcation using onboard FDL port. The FCS test for SD2 telegram was not implemented correctly.

- All PCD’s: When S-Bus IP Nodelist is used it’s possible that the communication using nodes does no more work after execute a download in run

- All PCD’s: XOB parameter as Registers does not work if 16bit addressing was used

- All PCD’s: LonFT10: SNVT_obj_status and SNVT_obj_request can be used in user profiles

- PCD3.Mxx60, PCD3.T6xx, PCD1.M2xx0, PCD2.M4x60: usage of I/O media mapping slows done the cycle time 2 times in comparison to FW 1.26.xx

- PCD2.M4x60: Download LonIP config not possible

- PCD2.M4x60: RTC gets sometime corrupted data when PCD7.F7500 is used on PCD2.M4x60

- PCD2.M4x60: RTC Time is wrong after several days of run

- PCD7.D443WTxR: uBrowser use alphapad.teq even if screen is rotated by 90°

- PCD7.D443WT5R: History entry Memory ‘Lost -1’ written in the History

- BACnet; Event Enrolment does not work correctly with external reference devices.

- BACnet; When using BACNet Webvisu the memory used increase each time the scheduler is edited.

- BACnet; PCD crash when BACnet Webvisu edit scheduler.

- BACnet; BACnet WebVisu does not display correct value for the WeeklySchedule value.

- BACnet; ACK Required bit in notification message is not set according to the related NV ack_required bits

- BACnet: The PCDAlarmStatus mapping property does not work correctly.

- BACnet: Mappings, which changed to the value 0 directly after a program download, are not updated correctly on the BACnet property.

- BACnet: The Priority-Array mapping does not work correctly after startup.

- BACnet: Initialization of Puls converter count with input reference gives error

- BACnet: Fix issue with weekly scheduler.

- BACnet: Fix issue with WeekNDay entries

- BACnet: The Restore functionality over BACnet does not work, when the PCD has been reset over factory reset.

- BACnet: The Action property in the command object does not handle NULL datatype and priority entries correctly, if they are used in the ActionCommand. Additionally, the Action property can now be read via index.

- BACnet: Priority_Array entry 16 will be overwritten on startup with the last Present_Value mapping

- BACnet: Out of Service -> Value for PV overridden after reboot by Input ref

- BACnet: The Log_Buffer to csv conversion for trend-log objects does not skip time change entries

- BACnet: Unmapped Priority-Array property array entries are not stored persistent

- BACnet: BACnet configuration on the PCD is not deleted when "unlinked" from PG5

- BACnet: Change Client Time_Of_Restart mapping to Unix time

- BACnet: Client mapping - Threshold is not implemented correctly

- BACnet: Mapped Reliability properties within analogue objects does interfere with the objects functionality. When the Reliability is mapped, the mapping has not full control over the property value.

- BACnet: The program download fails, when the BACnet config contained notification-class objects with event-counter mappings

- BACnet: BACnet Trend-Log(-Multiple) data can’t be retrieved as csv data

- BACnet: The SubscribeCOVProperty service can’t be executed on complete Priority_Arrays

Firmware 1.28.16 (June 2017)

New features

- All PCD's: When push button is pressed while power on then do not update FW from FS in order to execute a delete all.

- PCD1.M0xx0/M2xx0, PCD2.M4x60, PCD3.Mxx60, PCD3.M6880 and PCD3.T665/T666/T668:

Enhancement for HTTP server to transparently support sending compressed files.

Main corrections

- All PCD's SBUS parity mode, correction when NAK character is received as first byte of response.

- All PCD's: When download new Ethernet-RIO Program with the option ‘Delete all backups’ it can happen that the RIO is not commission and no goes no more in ‘data exchange mode’ until the PCD reboots.

- All PCD's: When RIO name is not in upper case the RIO file is not updated until a restart is executed.

- All PCD's: When RIO file is downloaded with download changed RIO file then RIO file is not sent to RIO until a restart is executed.

- All PCD's: Ethernet Frame Padding Information Leakage fixed (CVE-2017-9628)

- All PCD's: The Modbus CSF CloseSRPort does not free the port then a open/SASI call give an error and the port does not work.

- PCD1.M2xx0 PCD1.M22x0 PCD2.M4x60: PCD can crash while power down when XOB 0 is programmed.

- PCD1.M2xx0 PCD1.M22x0 PCD2.M4x60: MC0 mode with start/stop flag working again.

- PCD7.D443WT5R: Alarming does not work since 1.28.00 FW.

- PCD7.D443WT5R: When watchdog timeout occurs PCD7.D443WT5R does't reboot and stays locked.

Firmware 1.28.11 (Arpil 2017)

New features

- All PCD's: Support of BACnet Revision 14

Main corrections

- All PCD's: Various Open Data Mode fixes: Read Timeout enhancement, Client Connection timeout and Client Keep alive with anonymous port issue fixed

- All PCD's: Modbus RTU on all ports but specially on the F2xx module has been corrected to handle the response timeout processing in the case that the response is just occurring at the moment of the timeout.

- All PCD's: Battery status shows FAIL also if battery module is missing.

All PCD's: Various minor issues fixed - PCD1.M2xx0 & PCD3+: 38400/115200 baud settings adjustment

- PCD2.M4x60: PCD7.F7500 initialization

-

Remark about the firmware update on PCD3.M6860 or PCD3.M6880 CPU’s (FAQ #101988)

1.

On a PCD3.M6860/M6880 it always necessary to update both CPU’s (Main CPU and Extension CPU).

2.

It’s mandatory necessary to update first the firmware on the extension CPU, and after this the firmware on the main CPU. The firmware update can be done over any S-Bus PGU connection.

3.

The firmware 1.26.xx or greater, can be loaded only on a PCD3.M6860/M6880 with hardware version D or greater.

4.

It is not allowed to load a FW 1.26.xx or greater, to a PCD3.M6860/M6880 with an Hardware <D.

The latest FW which may be loaded in such a PCD is the FW 1.24.xx

5

If a firmware 1.26.xx or greater was loaded to PCD3.M6860/M6880 with Hardware <D, then it’s necessary to load again a FW 1.24.xx to the PCD

6.

If mistakenly the firmware on the main CPU was updated first, then it’s not possible to update the firmware on the extension CPU via the USB port of the Main CPU.

In this case, the update of the extension CPU must be done via the USB port of the CPU extension.

7.

It’s possible to put the extension CPU into the CPU firmware download mode by pressing the Run / Halt button on the extension at the power on of the PCD for 3 seconds. (marked with the red circle on the picture below)

The firmware download mode will be indicated then by two Leeds near to the Run / Halt button which are flashing alternatively green/red (one LED) and yellow the other LED.

To get to this Run / Halt button on the extension, you must remove the housing of the extension.

You will need to remove the battery module and any memory modules from the PCD and loosen the screw on the extension housing.

After, remove the housing.

The Run / Stop button is located next to the Run / Stop switch

-

What are the differences between the COSinus firmwares FW 1.24.67 and FW 1.26.31? (FAQ #101987)

In June 2017:

the COSinus FW 1.26.31 was released as maintenance version for the systems:- PCD1.M0xx0/M2xx0, PCD2.M4x60, PCD3.Mxx60, PCD3.M6880 and PCD3.T665/T666/T668.

the BACnet and LonIP FW 1.26.31 was released as maintenance version, which do support the BACnet Revision 9.

To support the BACnet Revision 14 it's necessary to use the PCD and the BACnet FW 1.28.xx.In March 2017:

the COSinus FW 1.26.28 was introduced into production for the systems:- PCD1.M2220, PCD1.Mxx60, PCD2.M4x60, PCD3.Mxx60, PCD3.M6880 and PCD3.T665/T666/T668.

the BACnet and LonIP FW 1.26.28 was introduced into production

In June 2016:

the COSinus FW 1.26.15 was introduced into production for the systems:- PCD1.M0xx0, PCD1.M2xx0, PCD2.M4x60, PCD3.Mxx60 and PCD3.M6880.

The COSinus FW 1.26.16 was introduced into production for the systems: PCD3.T665/T666/T668.

The BACnet and LonIP FW 1.26.15 was introduced into production

Attention:

The firmware 1.26.xx or later can be used only on the following PCD's with 8 MB onboard firmware memory:

PCD1.M0xx0/M2xx0, PCD2.M4x60, PCD3.Mxx60, PCD3.M6880 and PCD3.T665/T666/T668

The table below does show the hardware dependencies in relation with the COSinus firmware versions

Do use at least the PG5 firmware downloader version 2.1.311 or newer (included in PG5 patch 2.1.311 or newer) to prevent the loading of the FW 1.24.xx or 1.26.xx to a not compatible PCD.

Firmware 1.26.31 (June 2017)

Main corrections

- All PCD's SBUS parity mode, correction when NAK character is received as first byte of response.

- All PCD's: When download new Ethernet-RIO Program with the option ‘Delete all backups’ it can happen that the RIO is not commission and no goes no more in ‘data exchange mode’ until the PCD reboots.

- All PCD's: When RIO name is not in upper case the RIO file is not updated until a restart is executed.

- All PCD's: When RIO file is downloaded with download changed RIO file then RIO file is not sent to RIO until a restart is executed.

- All PCD's: Ethernet Frame Padding Information Leakage fixed (CVE-2017-9628)

- All PCD's: The Modbus CSF CloseSRPort does not free the port then a open/SASI call give an error and the port does not work.

- PCD1.M2xx0 PCD1.M22x0 PCD2.M4x60: PCD can crash while power down when XOB 0 is programmed.

- PCD1.M2xx0 PCD1.M22x0 PCD2.M4x60: MC0 mode with start/stop flag working again.

Firmware 1.26.28 (March 2017)

Improvements

- Text Ram can now be cleared (all chars are set to blank space) with the cgi interface by writing a zero length string.

- Ping request on ETH2 over rooter from different sub net.

- LonIP Mapper improvement

- Web Server RAM Disk increased

- Error Led not set on IR overflow

Main corrections

- All PCD's: MC0 communication with F2xx module and related communication flags are handled correctly in case of transmission

- All PCD's: Text Ram can now be cleared (all chars are set to blank space) with the cgi interface by writing a zero length string.

- All PCD's: Multiple AlarmLists with similar names will now be "initialized" correctly.

- All PCP's: TCP client keep alive is not working when anonymous port is used.

- All PCD's: Profi-SBus GWY does not wor, Profi-SBus Master/GWY stop working after cable is re plugged.

- All PCD's: PCD crash when use DIGI(R)/DIGO(R) with first parameter as FB parameter.

- All PCD's: Correction for modbus RTU communication over F2xx communication module

- All PCD's: When RIO file is downloaded with download changed RIO file then RIO file is not sent to RIO until a restart is executed.

- PCD1.M22x0: While changing the analog output value, the Watchdog is switching. Switching the Watchdog Relais over the corresponding flag has no influence.

- PCD2.M4x60: Sometimes the Profibus DP module is not initialized correctly on startup.

- PCD2.M5xx0: When Restore program because of a missing or dead battery configuration (SBus/IP,..) is not restored correctly.

- PCD2.M5xx0: Modbus RTU on all ports but specially on the F2xx module has been corrected to handle the response timeout processing in the case that the response is just occuring at the moment of the timeout.

- PCD2.M5xx0: Sometimes config is lost after download project with self-download tool.

- PCD3.Mxxx0: Battery status shows FAIL also if battery module is missing.

- PCD3.Mxxx0: FTP server processing with long commands resolved.

- PCD3.Mxxx0: Modbus RTU on all ports but specially on the F2xx module has been corrected to handle the response timeout processing in the case that the response is just occuring at the moment of the timeout.

- PCD3.Mxxx0: Sometimes config is lost after download project with self-download tool.

- PCD3.Mxx60: Profi-SBus/DP/SIO does not work on port 2 on PCD3.M3x60 & PCD3.M5360.

- PCD3.M6860: Ping request from over rooter from different sub net is not respond.

- PCD3.M6860/M880: Profibus/S-IO/Profi-SBus does not work stable.

- PCD3.M6860: Set PCD to HALT if there is no or incompatible media transfer between the two CPU's.

- PCD3.T66x: The RIO Status web page does not allow to clear the diagnostics.

- BACnet: The memory usage of the BACnet FW was increasing for every SubscrobeCOVProperty service, which has been received by the PCD.

- BACnet: A client configuration for Priority_Array properties in commadable objects (e.g. Analog-Value) does now allow reading (ReadProperty/COV) and writing (WriteProperty service to server) at the same time.

Firmware 1.26.15 (June 2016)

New features

- Support of PCD1.M2220-C15

- Support of PCD2.M4x60

- Support of PCD3.M3160/PCD3.M3360/PCD3.M5360

- Support of PCD3.M6880, PCD3.T668 Standby-CPU-System

Improvements

- PCD2.M4x6x, support Interrupt when reaching the configured ref Value

- PCD1.Mxxx0, PCD2.M4x60, PCD3.Mxx60 PCD7.D4xx: Increase None Volatile Register to 1000

- PCD3.T666/8: Increase the User Program Memory for to 256k

- PCD3.T66x: Support the ESIO manager use tag values for IP address

- PCD2/3.F2xx modules Baudrate: Support 300/600/1200 baud settings for in MC mode.

- S-Monitoring: In bar displays where the current time is visible, the average for the period is calculated not in a optimal way (time slice, ref time, is a bar). New it's displayed in seconds

Main corrections

- PCD3.M6860/M6880: When update FW on extension using the file system after update the extension FW can stay in an endless loop

- PCD3.M6880: crash wen Timmer/Counter is mapped in the Read Symbols

- PCD3.M6880: PCD can crash with MuKe Error when use the SBus GWY in parallel with modbus TCP

- PCD3.M6880: Standby CPU1 does not always HALT when CPU0 crash

- PCD3.M6880: CPU0 to 1 From Read data communication sometimes stop works

- PCD3.M6880: Add a Transmit Error diagnostic tag "DataTxErrors"

- PCD3.Mxxx0: Battery module on IO slot 3 does not show battery status in history

- PCD3.Mxxx0/PCD1.M2xx0: Some baudrates on onboard ports are not correct

- PCD2.M4x60: RTC read/write locks the PCD for about 30ms

- PCD2.M4x60: Modem does not work because of the not working DCD

- PCD3.T66x: Add ELine CSF library

- PCD3.T66x: Serial com does not work with SASI instruction

- PCD3.T66x: CSF Modbus Server Init gives an error when port 502 is used becasue this port is already open

- PCD7.D443WT5R: Assignation/Configuration of port 1 should return an error because port 1 is not supported

- PCD7.D443WT5R: Remove IO access from the system. PCD goes now in HALT with "INVALIDE OPCODE"

- PCD2.W220 with Pt1000: Significant deviation between singel channels

- BACnet: List Properties (like Date_List, Exception_Schedule, ...) could disappear after a PCD restart, if a WriteProperty request with an empty list value has been received for these properties before the restart. This behavior was only present for persistent properties

- BACnet: The Log_Buffer property of a Trend-Log object could not be read anymore using the ReadRange service, after a Event-Log or Trend-Log-Multiple has been read via ReadRange

- BACnet: Writing a single analog output channel is not working. The output is not changing. Writing output channels over the mapped functionality is working

- BACnet: PCD with BACNet loops with restart if program has "INVALIDE OPCODE"

- Restart Warm does not work

- SBus ELine has sometimes retries

- When create a Text/DB the backup fails until a restart is done

- PCD Crash with BUS ERROR on STXT instruction when text is empty

- Modem does not work correctly

- Modem does not work or PCD crash when modem is configure

- PCD can crash when error occurs in Modbus RTU

- The PCD crash if a BITI is executed with number as FB parameter

- PCD crash when use Profi-S-Bus Master

- Sometimes the program is lost when update FW from 1.24.xx to 1.26.xx

- MOVX/DIVX function where not working on Task or Temporary data when use indexed

- Add config tag value for GWY mode "data_no_secure" to deasble the secure data mode

- Not possible to upload a file through the Web server FTP interface (ftp.cgi or ftp.json) if that file starts with a white space character (either a space or a tab)

- CSF CopyDBBytesToR crash when destination is bigger than last Register

- Diagnostic Flags in S-Bus Master mode are not correct if there are collisions on the RS-485 network

- CSF Backup/Restore Media does give an error on restore when data change while backup/restore

- MOV instruction with type position as FB parameter gives error flag and fails

- Web-Alarm: Fix alarming color with "group color mode" and group bigger than 8

-

It’s possible to suppress the PCD Alarms on BACnet? (FAQ #101975)

Yes, it’s possible to suppress alarm notifications on BACnet by controlling the communication.

This is an official BACnet mechanism and available with BACnet firmware from 1.24.41 (or newer) and since PG5 2.1.420.To suppress the alarms it’s necessary to modify the BACnet communication mode of the device as described below.

In general, the communication of the BACnet device is controlled. There are 3 options:

- (0) Standard communication (default).

All requests will be answered and device will also send COV, Alarm or Event-notifications if necessary - (1) No communication.

The device will not answer to any request and does not send any COV, Alarm or Event-notifications. - (2) Reduced communication. The device will answer all requests, but does not send any COV, Alarm or Event-notifications.

This mode is usually selected if device is under maintenance and alarm notifications should be suppressed.

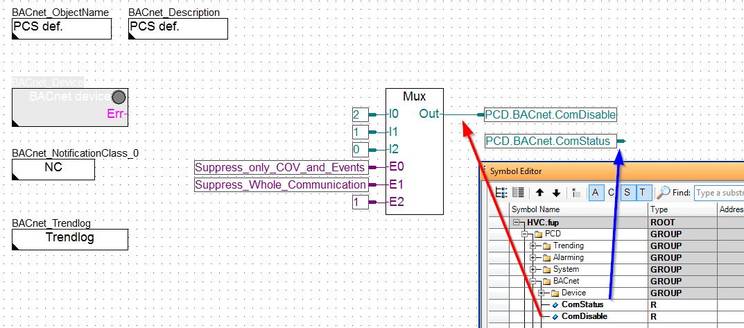

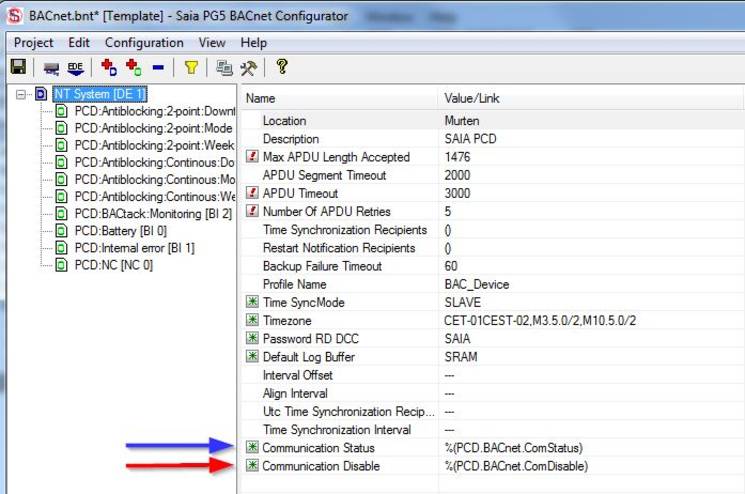

To control the communication mode as described above, 1 additional register must be defined and set to the corresponding value. A 2nd register can be used to get the current communication status.

In the example below, a “ComState” and “ComDisable” register has been defined. The “ComDisable” has to be controlled by application, e,g. via a maintenance switch at the cabinet or a software switch.

The “ComStatus” will show the actual communication status and is a read only.

Finally those 2 register have to be mapped within BACnet Configurator into Device object, property “Communication Status” and “Communication Disable”:

Good to know: DDC Suite 2.7 has implemented this mechanism into BACnet Device FBox for easier use.

If this two new items are used with a BACnet FW < 1.24.41 then BACnet does not start

- (0) Standard communication (default).

-

How to configure the analogue inputs of a PCD3.M90 to be able to connect an NTC10k temperature sensor? (FAQ #101974)

The analogue inputs of the PCD3.M90 CPU are able to handle NTC10k temperature sensors.

To be able to read an NTC10k sensor it’s necessary to make the following things:

1.Hardware configuration:

For the analogue inputs which does have connected NTC10k sensors, it’s necessary to set two jumpers on the PCD3.M90 I/O print on the selection of the input type (temperature, current, voltage)One jumper have to be put on the first two pins (for temperature)

The second jumper have to be put to the pins 3 and 4 (for voltage) as shown on the image below

2.Software:

Although it’s possible to select the sensor type NTC10k in the ‘DDC_M90 An_In’ F-Box, the output of this F-Box doesn’t provide the correct temperature value.

It’s necessary to place one of the two available 20 point linearization F-Box behind the analogue F-Box as shown on the print screen.

On the ‘DDC_M90 An_In’ F-Box do use the ‘default scaling’ for the ‘scaling’ parameter and the ‘NTC10’ or ‘1 : 1’ on the ‘mode selection’ option field.

Relation of the read out values to the temperature which need to be used on the 20 point linearization

F-Box.Value Temperature 72.4 70.0 118.4 50.0 147.1 40.0 177.6 30.0 192.7 25.0 207.3 20.0 233.8 10.0 255.2 0.0 271.1 -10.0 280.0 -17.7 284.7 -23.3 -

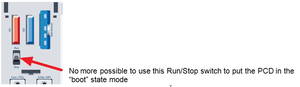

Why it’s no more possible to set the PCD3.Mxx6x in the firmware download mode with the help of the run/stop switch? (FAQ #101948)

On older PCD’s it was possible to set the PCD3.Mxx6x in to the firmware download mode by switching the run/stop switch (below the M1 memory slot) quickly several times during the start-up of the PCD.

On newer PCD’s it’s no more possible to set the PCD in the firmware download mode with this procedure.Reason:

New PCD3 power CPU’s (PCD3.Mxx6x) are delivered from factory with a new booter version.

This new booter version does change the behaviour of the Run/Stop switch on the PCD3 power CPU’s in that way, that it’s no more possible to put the CPU in the “boot” state mode by switching the Run/Stop switch (below the M1 memory slot) quickly several times during the start-up of the PCD.The “boot” state mode is used to download the FW in to the PCD.

The following systems are concerned:

• PCD3.Mxx60

• PCD3.Mxx67

• PCD3.Mxx80

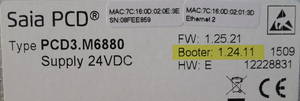

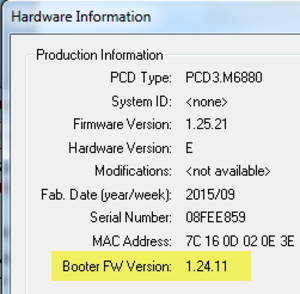

• PCD3.M96xxVersion number of the booter:

• 1.24.11 or newerHow to detect the booter version of a PCD?

Either with the information on white sticker on the back of the PCD

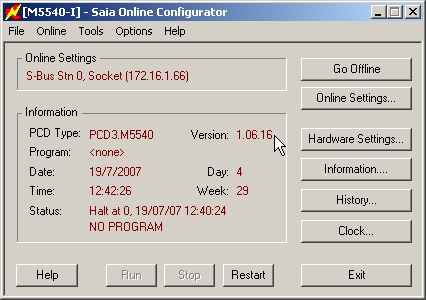

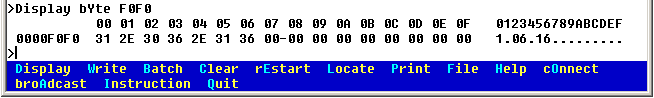

or from the hardware information of PG5 online configurator.

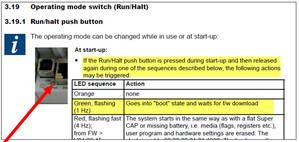

How to set the PCD in the “boot” state mode?

It’s possible to put the PCD in the “boot” state mode with the help of the Run/Halt

push button (near of the USB connector) as described in the PCD3 manual.Extract from PCD3 manual:

Remark:

Use the Run/Halt push button to put the PCD in the “boot” state mode.

This works on all PCD’s independent of the booter version.An update of the booter is not required on old PCD’s

-

How does the battery / power-up check work on the PCD? (FAQ #101929)

A 2,2 voltage of the battery is sufficient to keep the content of the SRAM memory of the PCD even if the PCD is not powered on with the 24VDC.

At power-up, the PCD checks if the battery or supeCAP voltage is less than 2.2. volt, and tests some patterns and signatures in the SRAM.

If one of those test gives an error the content of the SRAM is deleted, the PCD clock is reinitialized. If a Program Backup is available, a restore is done.

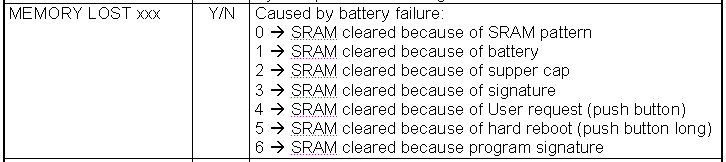

The entry "memory lost nn" is written in the History of the PCD where 'nn' stands for:

01: Bad or missing battery

02: Supercap voltage too low

03: Corrupted memory pattern/signature

04: RAM memory cleared by user (push button)

05: RAM and flash memory cleared by push button

06: Corrupted program header

10: Program restored due to CRC error

11: CRC error detected on program, but no backup was available for restoreRemarks

- In older FW < 1.10.04 the error message in the history was "Media corruption" instead of "memory lost"

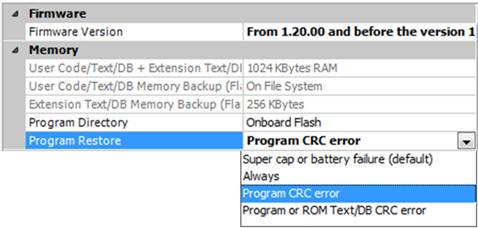

and the nn code was not implemented - New restore option since firmware version 1.20.00 and PG5 2.1:

On PCD2.M5xx0 and PCD3.Mxxx0, systems where the program is stored on SRAM, it is possible in the device configurator of PG5 to enable a CRC check.

The test is done over the program or the program and the ROM Texts/DBs.

In case of CRC error, the program is restored and the entry "memory fail 10" is written in the History of the PCD.

If there is no program backup, and therefore it's not possible to do the restore, the History entry "memory fail 11" will be written.

- In older FW < 1.10.04 the error message in the history was "Media corruption" instead of "memory lost"

-

What are the differences between the COSinus firmwares FW 1.22.48 and FW 1.24.69? (FAQ #101921)

In June 2017 the COSinus FW 1.24.69 was introduced into production for the systems PCD2.M5xx0, PCD3.Mxxx0. The corresponding BACnet and LonIP firmware is available on the support homepage.

In March 2017 the COSinus FW 1.24.67 was introduced into production for the systems PCD2.M5xx0, PCD3.Mxxx0. The corresponding BACnet and LonIP firmware is available on the support homepage.

In Mai 2015 the maintenance COSinus FW 1.24.30 was published for the systems PCD1.M0xx0, PCD1.M2xx0, PCD2.M5xx0, PCD3.Mxxx0, PCD3.Mxx60 and PCD7.D4xxxT5F.

In February 2015 the COSinus FW 1.24.25 was introduced into production for the systems PCD1.M0xx0, PCD1.M2xx0, PCD2.M5xx0, PCD3.Mxxx0, PCD3.Mxx60 and PCD7.D4xxxT5F.

In August 2014 the COSinus FW 1.24.05 was introduced into production for the systems PCD1.M0xx0, PCD1.M2xx0, PCD2.M5xx0, PCD3.Mxxx0, PCD3.Mxx60 and PCD7.D4xxxT5F.

In September 2014 the COSinus FW 1.24.09 was introduced into production for the systems PCD2.M5440 and PCD2.M5540Attention:

The firmware 1.24.xx can be used only on PCD’s with 8 MB onboard firmware memory.

The table below does show the hardware dependencies in relation with the COSinus firmware versions

Do use at least the PG5 firmware downloader version 2.1.311 or newer (included in PG5 patch 2.1.311 or newer) to prevent the loading of the FW 1.24.xx to a not compatible PCD.

Firmware 1.24.69 (June 2017)

Improvements

- All PCD's: SBUS parity mode, correction when NAK character is received as first byte of response.

- All PCD's: When download new Ethernet-RIO Program with the option ‘Delete all backups’ it can happen that the RIO is not commissioning and don't goes anymore in ‘data exchange mode’ until the PCD reboots.

- All PCD's: When RIO name is not in upper case the RIO file is not updated until a restart is executed.

- All PCD's: When RIO file is downloaded with download changed RIO file then RIO file is not sent to RIO until a restart is executed.

- All PCD's: Ethernet Frame Padding Information Leakage fixed (CVE-2017-9628)

- PCD2.M5xx0 PCD3.Mxxx0: Self-download tool, sometimes config is lost after download of the project.

Firmware 1.24.67 (March 2017)

Improvements

- New Conversation Table for W380 Ni1000 and PT1000 Temperatur

- S-Bus Serial UART Diagnostics not correct

- Various Open Data Mode fixes: Read Timeout enhancement, Client Connection timeout and Client Keep alive with anonymous port issue fixed

- LonIP Mapper improvement

- Modbus Communication error on F2 module

- Program Restore issue fixed when restore from file system flash card

- New PLC Start configuration after Crash added

- Profi-SBus Master stop working when cable is broken

- Various minor issues fixedOpen Data Mode: Data loss if at the same time the connection was closed by the partner

Maintenance firmware 1.24.30 (Mai 2015)

Main corrections

- Web-Server: WebFTP supports correctly encoded characters like “/”, “&” in the web-requests

- Web-Server: ftp.cgi fails to parse the MIME multipart request when boundary string is enclosed in double quotes

- Web-Server: Enable Web-Server CGI access from SBC.NET

- Web-Server: Sometime a modified file was not recognized and therefore not updated in the browser

- Open Data Mode: Data loss if at the same time the connection was closed by the partner

Firmware 1.24.25 (February 2015)

Improvements

- Enhancements and improvements regarding the communication with the new E-Line modules.

Main corrections

- COPYX instruction: the destination is new indexed when a timer/counter is used as destination.

- STXMX / SRXMX instructions are working correctly.

- I/O modules:

- PCD2.G200: temperature is correctly calculated when Ni100 L&S is selected

- PCD2/3.W380: support for hardware revision B conversion factor for current inputs has been updated. - Correction regarding PCD3.M6860: support for the new hardware version

Firmware 1.24.09 (September 2014)

New features- Only for PCD2.M5440 and PCD2.M5540

Recognition of the new type of 8 MB onboard flash integrated in the PCD2.M5xx0

Main corrections

- STXMX and SRXMX instruction make the PCD to crash and reboot

- Write Periphery Byte (WRPB) doesn't work

- Data Exchange for W5300 module does not work anymore

- Modbus error when port is doubled assigned.

Firmware 1.24.05 (August 2014)

New features- Support of the following modules

- PCD7.W600

- PCD7.R610 - Easy update functionalities => FW update & restore of the application including the Web pages from a *.sprg file.

- LON FT-10

- New SFs and communication driver for the E-Line devices

- New test functions:

- Backup check (TEST 8)

TEST 8 give the possibility to check in the application program if a Backup file is present and if it is the correct one.

- FW check (TEST 40)

After an unsuccessful FW update, it could append that there is no more FW in the FLASH memory but the system is able to run with the "old" FW until next power off.

The test 40 function allow to detect such a situation.

Improvements

- BACnet Web interface

- 5 min logging in the S-Monitoring

- New SFs in the system library: MD5 hash and AES, DES, 3DES cipher encryption

- Improve the robustness of the system against Ethernet storm

- PCD Modbus client, allow the reception of server answer also if the reply of the server is to fast

(< 3.5 character time as defined in the modbus specification)

Modification doesn't apply for F2xx ports, but only for on-board ports

Main corrections

- Modbus:

- PCD Modbus client, read binary F-Box does show a error, but the function is correctly executed and the data's are correctly processed

- PCD Modbus server, 32 bits not correctly written to the PCD medias if several consecutive modbus telegrams are received in the PCD - When an additional Alarming2 configuration (*.asv file) is present in the PCD, the program is blocked in the start-up sequence

- The XON XOFF SASI mode (MC2) does not work on PCD2.M5xx0 port 2

- If the a Smart RIO or Smart RIO manager is disabled with the tag, the manager still sends the configuration to the RIO

- The Program Restore when CRC Error occurs the program is only restored if there is not already a restore done (manual or automatic)

- The PCD Crash with a Bus Error when it is restarted while sent a SMS

- PCD3.M6860 IP on extension stops when extension reboots

- PCD2/3.W380 linearization works only correct if the absolute value of min and max are equal

- On PCD1.M0/M2, PCD3.Mxx60 and PCD7.D4xxxT5F the memory dump is aborted by reading the SRAM

- On Open Data Mode when the TCP connection timeout elapses, the connection remains open while XBSY flag is reset

- Corrections in relation with S-Monitoring

- Corrections in relation with the E-Line modules

- Corrections in relation with BACnet and LON

-

Why the status overflow flag of the onboard analogue inputs of the PCD1.M0, PCD1.M2, PCD3.M2x30V6 (PCD3 Compact) and PCD3.M2x30A4Tx (PCD3 WAC) does show an over-flow in the middle of the measurement? (FAQ #101864)

Due of an error on the FW the overflow status flag of the onboard analogue inputs does not work correctly.

This flag was set to high in the middle of the measurement range and not if the maximum value was reached.

The error occurs on all onboard analogue inputs independent if the analogue input is used for current, voltage or temperature signals on the following PCD’s.

- PCD1.M2

- PCD1.M2 (PCD1.Room)

- PCD1.M0 (PCD1 E-Controller)

- PCD3.M2x30V6 (PCD3 Compact)

- PCD3.M2x30A4Tx (PCD3 WAC)

Solution:

Use the new FW which does fix the error.

The FW is available on the support homepage and it's possible to update the firmware with the

PG5 firmware downloader tool.

For the PCD1.M0/M2 the error was fixed in the PCD firmware.

For the PCD3 Compact and PCD3 WAC, the error was fixed on the dedicated IO-Board FW

Overview about the FW which does fix the problem:

For the PCD1.M0/M2:System PCD

Firmware versionPCD1.M0/M2 1.20.39

For the PCD3:System IO-Board

Firmware versionMinimum HW version of the PCD

which support the new IO-Board FWPCD3.M2x30V6 Compact 022 B PCD3.M2x30A4Tx WAC 1.00.13 A

-

It's possible to connect a Ethernet Port of a PCD directly to Power over Ethernet (PoE)? (FAQ #101847)

No, do not connect the RJ45 connector of a Ethernet Port of a PCD directly to Power over Ethernet (PoE).

The RJ45 Ethernet port of the PCD will be destroyed if connected directly to PoE (Mode B) because our Ethernet port (PCD7.F655 or the integrated Ethernet ports on the PCD1.M0/M2, PCD2.M5 and PCD3 and all Panels with Ethernet ports) are not designed for this purpose.

Possible solution to connect PCD to Ethernet networks where PoE is used:

1.

Split the Ethernet network in a section where PoE is used and in to a section where PoE is not used and connect the PCD in to the section where PoE is not used.

The splitting of the network could be achieved with routers which do have on one side connectors with PoE and on the other side connectors without PoE.

2.

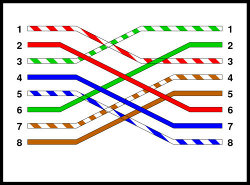

Use a special Ethernet cable where the blue/blue-white and the brown/brown-white wires are disconnected.

(On PoE Mode B; the Pin 4 and Pin 7 of the RJ45 Ethernet connector are used to supply the power of PoE to the card,

On the PCD the Pin 1, 2, 3, 6 of the RJ45 Ethernet connector are uesd for the Ethernet communication)

-

Why is there an offset to the current PCD time in the Trending timestamp of a Web project if the FW 1.20.nn is used? (FAQ #101834)

If on the PCD the FW 1.20.nn is used and if on the device configurator a time zone is defined then it's possible that on the S-Web Trend Macro the time stamp of the trend values are displayed with a time stamp offset.

Symptom

The time stamp of the trend values on a S-Web trend does not have the same time as the PCD time (read e.g. with PG5).

The time stamp of the trend values are time shifted for several hours (depending of the selected time zone configured in the PG5 Device Configurator)

Also other macros could have this problem if the PCD instruction SYSRD 7090 is used in the PCD code to read out the PCD time.

Reason

The problem is because on the FW version 1.20.nn the instruction 'SYSRD 7090' (=> Read UNIX TIME) give back the number of seconds since 1.1.1970 00:00:00 as UTC time and not as local time.

On FW < 1.20.nn the instruction give back the time as local time.

Other reason

The default Container on the Web Editor project 'MB_tmz_en' is set to 1.

If you want that the timestamp of the trending corresponds to the time of the PCD this Container should be set to 0.

Solution

In the FW 1.22.nn and later the timestamp is again in local time and a new instruction is introduced 'SYSRD 7190' which gives back the value of seconds in UTC.

The FW 1.22.nn will coming out end of June 2013 -

What does the history message 'MEMORY LOST n' mean? (FAQ #101830)

In the history of the PCD, different memory lost code can be displayed.

The number beside the memory lost message does give a more precise description why the memory was cleared.

See the table below to know the reason for the memory clearing.

-

On PCD2.M5 and PCD3 CPU's without Ethernet port and equipped with the FW 1.20.25, it's not possible to communicate over the port 0 and 1. (FAQ #101823)

Due of a firmware error on the COSinus FW 1.20.25 it’s not possible to communicate over RS232 on the

port 0 of the PCD2.M5440

and

port 1 of PCD3 CPU’s, but only on PCD’s without Ethernet port.

The error is fixed since the FW 1.20.31.

Also the FW 1.16.69 doesn’t have this error.

PCD’s equipped with a Ethernet port doesn’t have this error.

The concerned PCD’s are:

• PCD2.M5440 (port 0 / RS232)

• PCD3.M6440/M5440/M3230 (port 1 / PCD3.F121)

• PCD3.M3020 (port 1 / PCD3.F121)

• PCD3.M2030V6 (port 1 / PCD7.F121S)

• PCD3.M2230A4T5 (port 1 / PCD7.F121S)

Communication over RS485 works fine.

-

What are the differences between firmware 1.16.69 and COSinus FW 1.22.61? (FAQ #101820)

In January 2014 the COSinus FW 1.22.28 was introduced into production for the systems PCD1.M0xx0, PCD1.M2xx0, PCD2.M5xx0, PCD3.Mxxx0, PCD3.Mxx60, PCD3.T665/T666 and PCD7.D4xxxT5F.

The FW 1.22.61 is the latest maintenance firmware for PCD's with 4 MB firmware memory.Firmware 1.22.61 (February 2017)

New features- Re-trigger ODM Read Timeout on each read CSF

- ODM Generate Disconnect event even if Server calls the disconnect

Main corrections- Sometimes configuration is lost after download project with self-download tool

- PCD crash when use DIGI(R)/DIGO(R) with first parameter as FB parameter

- If PCD2/3.W220 with Pt1000 is used a Significant deviation between channels

- Improved HTTP session handing: Session cookies have now httpOnly flag set

- BUS ERROR on STXT instruction if text is empty

- Add config tag value for GWY mode "data_no_secure" to deasble the secure data mode

- PCD crash sometimes on download when Smart RIO are not present

- If broadcast data exchange is used the output telegram is send to only one RIO after a reboot

- The diagnostic Flags in S-Bus Master mode are not correct if there are collisions on the RS-485 network

- CSF CopyDBBytesToR crash when destination is bigger than last Register

- When create a Text/DB the backup fails until a restart is done

- W380 shows wrong values for PT1000 and PT1000L&S

- When starting an application with an alarm list name too long (> 25), the PCD halts with a BUS ERROR

- On PCD7.45x_EM, P-Web panel, Alarm list not loaded after URL jump on a GWY station

- The ACCU not set High at the begin of the XOB

- MB display, red cross if picture filename is empty

- MB display, when scrolling in a Web Editor trend, there was some curve drawing issue

- Updates on the HDLog trends are not displayed on the Microbrowser App

Firmware 1.22.48 (March 2015)

Main corrections- FTP error due of username

- cgi access trough SBC.NET

- Solved problem when downloading .sprg file in PG5 with download HTTP

- History Message CALL LEVELS shows wrong numbers in the text

Program address is displayed in the level field - Fix Profi SIO communication on PCD3.M90, port 10

Firmware 1.22.46 (October 2014)

New features- Support of the PCD7.R610 module

- only as file system memory for the PCD.

Not supported are on the PCD7.R610:

- Easy update functionalities => FW update & restore of the application including the Web pages from a *.sprg file.

-> this functions need the FW 1.24.xx

Main corrections- When an additional Alarming2 configuration file (*.asv file) is present in the PCD, the programm is blocked in the start-up sequence.

- The default GWY is not update correct if the IP address is received from the DHCP server. Only the Global Routing table is updated.

- Backup/restore doesn't work always on PCD3.M90 or OEM (Zxx) systems

- Program Restore with CRC Error

The program restore when CRC Error occurs the program is only restored if there is not already a restore done (manual or automatic) - Improving Performance of PLC in case of Ethernet-Bombarding

Firmware 1.22.28 (January 2014)

New features- SBC Logo change

- Security Update

- Per default, FTP, Web-Server and S-Bus over IP are deactivated

- IP filtering

- New password mechanism for web-server access

- SFCs for AES128 encryption/decryption

- Dynamic password for FTP (service key)

- FTP Passive mode

- Support new Analog Input Module W380

- Support PCD2.G200 for PCD1.Mxxx0 & PCD2.M5xx0

- Mapping of the PCD3.Mxx60 Interrupt Inputs

- SF to convert time std<->unix time

- Modbus Master, intercharacter timeout on the slave answer as parameter

Main corrections

- FTP data connection error, when downloading many files (more than 150 files) the data connection channel can not be open anymore

- File System compression error if automatic compression is used.

When the auto compression is active and a "big" file is transfered over FTP (download time > 5 sec), the compression is aborted due to remaining open file.

After abortion, the compression check is no more executed when downloading file(s) - Interpreted texts are not working properly

Correction of bugs with $bxxxx.yyyyy, @xXnnnnn, $AXnnnnn - PCD1.M2110, does allow to access 10 S-Bus or Modbus slaves, now its possible to access 10 slaves independently of their addresses (was 0..9 address range till now)

- Corrections in relation with BACnet and LON.

Firmware 1.20.25 (March 2013)

Main new Features / Extensions- Following new systems are supported:

PCD1.M0160 ;PCD1 EnergyPlus Controller

PCD1.M2110R1 ;PCD1 Room Controller - Following new modules are supported:

PCD7.R550M128 ;128MB memory card

PCD7.R582 ;128MB memory card with LON/IP

PCD2.F2150 ;BACnet MS/TP com. module

PCD2.F2400 ;LON FT-10 com. module - Support up to 16384 Flags and 16384 Register

- S-Monitoring

- Download in Run

- File System improvements (e.g. date)

- BACnet extensions (e.g. MS/TP)

- LON extensions (e.g. FT-10)

- Access to config parameters via TAGs

Improvements

- Introduce "first time init data" in the restore process

- Improve the reliability of the file system

-

Why the MPI adapter doesn’t work on the MPI port of the PCD3.M5547, PCD3.M5567, PCD3.M5540, PCD3.M5440 or PCD3.5560? (FAQ #101814)

The external MPI adapter which can be connected to the MPI Port of the PCD does need to be supplied with 24VDC.

Depending of the hardware version of the PCD, on some FW this 24VDC supply on the MPI doesn’t work.

The table below does show the dependency between the hardware and the firmware in relation with the 24VDC supply on the MPI port.

Classic PCDPCD3.M5540

PCD3.M5440FW 1.16.52

FW >= 1.16.69

HW F

ok

ok

HW G1

No 24V on MPI

ok

PCD3.M5560

FW 1.16.52

FW >= 1.16.69

HW A1

ok

ok

HW B

No 24V on MPI

ok

xx7 PCDPCD3.M5547

FW 1.10.17

FW >= 1.16.61

HW F

ok

ok

HW G1

No 24V on MPI

ok

PCD3.M5567

FW 1.16.50

FW >= 1.16.71

HW A1

ok

ok

HW B

No 24V on MPI

ok

-

On a NT PCD the S-Bus slave gateway port doesn't communicate after programm restart of the gateway PCD! (FAQ #101802)

If for example a Scada system communicate over S-Bus slave gateway port or S-Bus PGU port with a slave station via a master gateway port then after a programm download to the gateway PCD (or if the gateway PCD is restarted) the S-Bus slave gateway port or the S-Bus PGU port of the gateway SPS is blocked.

In order to communicate again through this ports a system reboot (powerup) of the gateway SPS is needed.

This problem could occur on all communication channels between the PC and the PCD (USB, serial, TCP)

Remarks:

This problem appaers when the gateway station is also communicating with its slave station over the gateway master port!

Solution:

Update the firmware of the gateway SPS to the version 1.16.74 or later. -

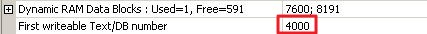

Which Texts are writeable/editable during Runtime on a PCD? (FAQ #101801)

This FAQ explains under which circumstances, which texts are writeable/editable during runtime.

Non-Saia PCD® COSinus Systems (PCD1.M1xx, PCD2.M1xx)

With Flash or EPROM Memory plugged

- Texts < 4000 are not writeable in runtime

- Texts >= 4000 are writeable in runtime

With RAM Memory plugged

- Texts < 4000 are writeable in runtime but PG5 recognizes if one of these texts has changed*

- Texts >= 4000 are writeable in runtime

Saia PCD® COSinus-Systems

PCD3.Mxxx0 and PCD2.M5xx0

- Texts < 4000 are writeable in runtime but PG5 recognizes if one of these texts has changed*

- Texts >= 4000 are writeable in runtime

PCD3.Mxx60 and PCD1.M2xx0

- Texts are configurable in the Build Options, define First Writeable Text.

*If one of these texts have changed, PG5 will give a message when you want to go online with PG5 indicating that the

program is not the same. Also these texts will be overwritten when the program is downloaded again. -

Lifetime expectancy of the Renata Lithium battery on recent PCD compared to previous PCD generations (FAQ #101780)

It is correct that the indication of a low battery will appears earlier due to more accurate prediction on a new Saia PCD® COSinus system than before on a PCD2/1.M1xx.

There are two main reasons to explain this fact:

- The supervision function was improved

The new battery supervision function sets the battery under a very small load to predict the end of battery capacity. In term of battery capacity, this additional load is negligible, but allows the system to warn before the battery is really empty. That gives enough time to exchange the battery and preventing memory lost. This is not the case on the previous generation, where only the voltage was supervised.

- There is more memory to support

The recent systems have much larger memory; the resulting standby current to be supplied from the Battery increased short the time duration.

Summary of working principle with the Lithium Battery

System with passive battery supervision applied on the following PCD’s:

PCD1.M130, PCD1.M135, PCD2.M110, PCD2.M120 and PCD2.M150

The voltage of the battery is supervised.

SBC advise to change the battery all 1 - 3 years.System with active battery supervision since 2001 applied on the following PCD’s:

PCD1.M2xxx, PCD2.M170, PCD2.M480, PCD2.M5xxx, and PCD3.Mxxxx

If the 24VDC power is switched on, then the voltage of the battery is measured during short time all 12 seconds where the battery is submitted to a small discharge.

This allows to warn the application program before the capacity of the battery reach its end.

We estimate that in this case the battery has still two days of reserve capacity for the changing of the battery.

In most recent PCD's the battery change can be done from end-user keeping the 24VDC power supply of the PCD switched ON.

If during the battery change, the 24VDC power supply of the PCD remains switched ON then there is no lost of the SRAM content (means that the PCD medias does retain there values)A lost of the SRAM content (PCD medias like registers, flags and the application program [application program only if there is no application program stored in the Flash memory] does occurs only if the 24VDC power supply is switch off during the battery change.

The specifications in the manual concerning the typical life time of a Renata battery is still correct (1-3 years).

Today, on April 2013 we are able to give more precise lifetime expectancy for the battery for PCD’s produced since July 2012:Service conditions Lifetime expectancy of the battery a. continuous power OFF 24 Months b. power ON 8 hours on 5 days a week 34 Months c. continuous power ON 80 Months

However SBC advices to preventable change of the Lithium battery all 5 yearsNote that these values are set conservatively; longer lifetime of the battery can be achieved in the practice.

For PCD’s produced before July 2012, above mentioned times could be shorted by 20% due to larger SRam standby current.

The value of standby current is verified on each device during the production. -

How the RS485 bus is terminated if on a PCD3.M5340 the bustermination of the port 3 is activated? (FAQ #101753)

On the PG5 device configuratior it’s possible to activate/deactivate the RS485/RS422 Bus termination of the port 3 (D-Sub #2 connector; RS485/RS422) of the PCD3.M5340.

If the Bus termination is activated then the following resistors are used.

For RS485 and RS422:

Remark for the RS422:

The following resistors are always used, independent if the bus termination is activated or deactivated on the device configurator.

-

What is the signification of the history entry "Resisters Fail"? (FAQ #101722)

Due of a firmware error it's possible that on the history of the PCD3.M5340 there is an entry "Resistors Fail".

Symptom

When trying to enable the termination resistors of port 3 of a PCD3.M5340 (produced beginning of 2012) the entry "RESISTERS FAIL" is entered in the PCD history.

Reason

If this error is shown in the PCD history, then it isn't possible to use the RS485/RS422 termination resistors for the port #3 of the PCD3.M5340 (RS485/RS422 port on the 9-pole D-Sub connector) due to a firmware restriction.

Solution

Please update the PCD firmware to version 1.16.60 or later. This firmware can e.g. be found in the lates BACnet firmware maintenance package.

Remark

The communication on the port #3 is possible without problems given the termination of the bus is realized externally. -

Why is the modem "MDLS144 onbit" no longer working on a new PCD? (FAQ #101718)

If the "MDLS144/288 Data9600 onbit" modem is connected to a "non Saia PCD® COSinus" system (PCD1.M1, PCD2.M1) then it's possible to establish a modem connection to those systems but if the same modem is connected to a "Saia PCD® COSinus" System (PCD1.M2, PCD3, PCD2.M5) then it isn't possible to establish a connection.

The reason of this behavior is the difference how the FW of the PCD does handle the modem.

In general the FW does send the as first step the "modem reset sting" and after this the FW does check the status of the DSR / CTS signal before in a second step the "modem initialization string" is send to the FW.

- On the "non Saia PCD® COSinus" systems the DSR or the CTS signal have to be high before to go to the second step.

- On the "Saia PCD® COSinus" systems the DSR and the CTS signal have to be high before to go to the second step.

Solution

To use the "MDLS144/288 Data9600 onbit" modem on "Saia PCD® COSinus" systems its necessary to set the DSR to high during the first step of the modem initialization.

To do this it's necessary to adapt the "modem reset sting" on the device configurator/HW-settings on Saia PG5® .

The "modem reset string" has to be changed from:

AT&F\r

to:

AT&F&S0\r

Remarks

The "modem initialization string" remains the same.

The modification could be used on "Saia PCD® COSinus" system as also on "non Saia PCD® COSinus" systems. -

Why does the PCD no longer run due to "BNt FAIL AI00006"? (FAQ #101712)

In case the "PCD input reference" is used in the BACnet configuration and a persistent value is written in runtime over BACnet (with BACnet firmware 1.16.41), the PCD might no longer be able to read the configuration on next power up. As result the PCD remains in HALT and writes e.g. "BNt FAIL AI00006" into the history.

Symptom

In case the "PCD input reference" is used in the BACnet configuration and a persisten value is written in runtime over BACnet (with BACnet firmware 1.16.41), the PCD might no longer be able to read the configuration on next power up. As result the PCD remains in HALT and writes e.g. "BNt FAIL AI00006" into the history.

Reason

When writing a persistent value to BACnet and if the "PCD input reference" is used, the configuration stored in the flash memory is destroyed with firmware version previous to 1.16.59 (e.g. 1.16.41).

Solution

In case you use the "PCD input reference" and in case your BACnet configuration contains over 100 inputs (e.g. 60AI and 50 BI) please update the BACnet and PCD firmware to BACnet FW 1.16.59 and PCD FW 1.16.57 or later. This firmware can be downloaded from the support site.

Remark

Please note that the PCD only writes the error message into the history, but PG5 shows a message saying "Everyting is OK". -

Why does the user program no longer work correctly after a restore from flash? (FAQ #101680)

In case user program is restored from flash with a PCD3 or PCD2.M5540 with firmware 1.16.xx it is possible (depending on the device configuration) that the restored user program is not complete.

Symptom

The user program of a PCD3 or a PCD2.M5540 is no longer running correctly (one of the program blocks is no longer executed) after it has been restored from flash. This phenomenon can occur with firmware 1.16.xx and if no extended header is present in the device configuration (this means that no IP address, no modem configuration and no gateway is configured).